Unlocking Efficiency: How ZDS Vibrating Screen Enhances Material Separation

Release time:

Aug 02,2025

Unlocking Efficiency: How ZDS Vibrating Screen Enhances Material Separation Table of Contents 1. Introduction to ZDS Vibrating Screen Technology 2. Understanding Material Separation in Manufacturing 3. Importance of Efficient Material Separation 4. Key Features of the ZDS Vibrating Screen 5. How ZDS Vibrating Screen Enhances Material Separation 6. Applications of ZDS Vibra

Unlocking Efficiency: How ZDS Vibrating Screen Enhances Material Separation

Table of Contents

- 1. Introduction to ZDS Vibrating Screen Technology

- 2. Understanding Material Separation in Manufacturing

- 3. Importance of Efficient Material Separation

- 4. Key Features of the ZDS Vibrating Screen

- 5. How ZDS Vibrating Screen Enhances Material Separation

- 6. Applications of ZDS Vibrating Screen in Various Industries

- 7. Benefits of Using ZDS Vibrating Screen

- 8. ZDS Vibrating Screen vs. Traditional Material Separation Methods

- 9. Conclusion

- 10. FAQs

1. Introduction to ZDS Vibrating Screen Technology

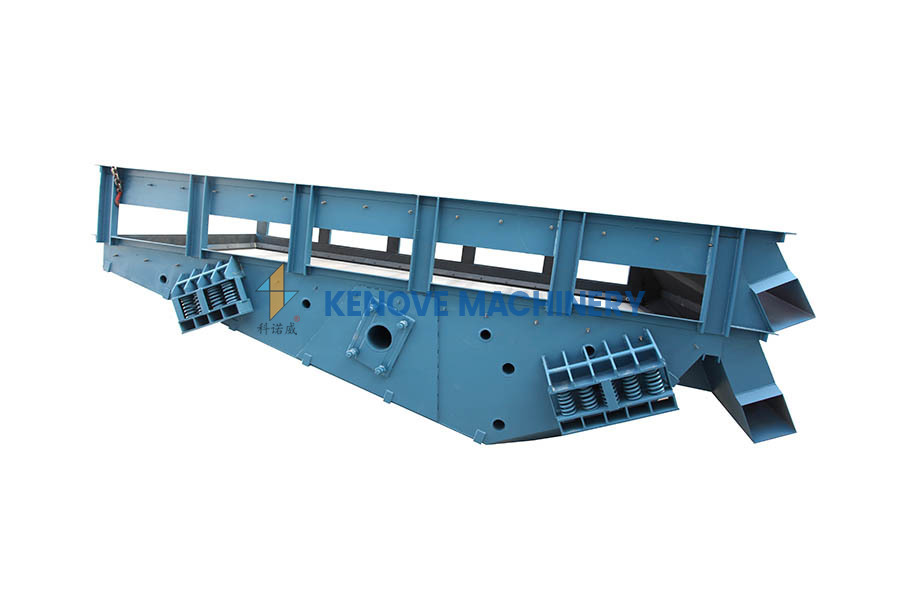

The ZDS Vibrating Screen represents a significant advancement in **material separation technology**. Designed to optimize manufacturing processes, it offers unparalleled efficiency and precision in separating different materials during production. As industries continue to evolve, the demand for innovative solutions like the ZDS Vibrating Screen becomes increasingly critical. This article delves into the mechanics of this cutting-edge equipment, its benefits, and how it can transform your material processing operations.

2. Understanding Material Separation in Manufacturing

Material separation is the process by which different materials are sorted or divided based on specific characteristics such as size, shape, density, or composition. In manufacturing environments, effective material separation is essential to ensure quality control, improve efficiency, and enhance overall production rates. The **ZDS Vibrating Screen** is designed specifically to address these needs, providing manufacturers with a reliable tool for efficient material sorting.

3. Importance of Efficient Material Separation

Efficient material separation plays a crucial role in various manufacturing sectors, including construction, mining, and recycling. The ability to quickly and accurately separate materials can lead to:

- **Increased Productivity**: Reducing downtime and optimizing workflow.

- **Cost Savings**: Minimizing waste and improving resource utilization.

- **Enhanced Quality Control**: Ensuring that only materials meeting specific standards proceed to the next stage of production.

- **Environmental Benefits**: Facilitating better recycling practices and reducing landfill waste.

Understanding the significance of efficient material separation is vital for any manufacturer looking to improve their processes and remain competitive.

4. Key Features of the ZDS Vibrating Screen

The **ZDS Vibrating Screen** boasts several features that set it apart from traditional separation methods:

4.1 High Screening Efficiency

The ZDS model is engineered to maximize screening efficiency, enabling it to perform well even in high-volume environments. Its unique design ensures that materials are evenly distributed across the screen surface, enhancing separation.

4.2 Adjustable Frequency and Amplitude

Users can easily adjust the frequency and amplitude of the vibrations, allowing for customization based on the specific materials being processed. This flexibility is essential for achieving optimal results in different applications.

4.3 Durable Construction

Constructed from high-quality materials, the ZDS Vibrating Screen is designed to withstand harsh operating conditions. Its robust build guarantees longevity and reliability, minimizing maintenance costs over time.

4.4 Minimal Noise Operation

Unlike many traditional separation machines, the ZDS Vibrating Screen operates with reduced noise levels. This feature not only enhances the working environment but also complies with regulatory standards for noise pollution.

5. How ZDS Vibrating Screen Enhances Material Separation

The effectiveness of the ZDS Vibrating Screen in enhancing material separation lies in its innovative design and advanced technology. Here are some ways in which it optimizes the separation process:

5.1 Effective Particle Size Distribution

The ZDS Vibrating Screen utilizes a multi-layer design that allows for the effective separation of particles based on their size. This ensures that materials of different dimensions are sorted accurately, reducing the chances of contamination or mixed batches.

5.2 Improved Flow Dynamics

The unique screening surface of the ZDS Vibrating Screen facilitates better flow dynamics. This improvement leads to faster processing times and enhances the overall efficiency of material handling.

5.3 Enhanced Material Recovery Rates

By optimizing the separation process, the ZDS Vibrating Screen significantly improves material recovery rates. This is especially beneficial in industries where the goal is to reclaim valuable materials from waste streams.

6. Applications of ZDS Vibrating Screen in Various Industries

The versatility of the ZDS Vibrating Screen makes it suitable for a range of applications across different industries:

6.1 Mining and Minerals Processing

In the mining sector, the ZDS Vibrating Screen is used to separate minerals from waste material efficiently. Its high screening capacity is ideal for handling large volumes of raw materials.

6.2 Recycling and Waste Management

The ZDS Vibrating Screen plays a critical role in recycling operations by helping to sort recyclable materials from non-recyclables effectively. This contributes to more sustainable waste management practices.

6.3 Construction and Demolition

During construction and demolition projects, the ZDS Vibrating Screen is employed to separate different materials such as concrete, wood, and metal, facilitating proper disposal and recycling.

6.4 Food and Beverage Industry

In food processing, the ZDS Vibrating Screen is utilized to ensure that only high-quality materials are used in production. Its ability to accurately sort ingredients is crucial for maintaining product quality and safety.

7. Benefits of Using ZDS Vibrating Screen

The adoption of the ZDS Vibrating Screen offers a multitude of advantages for manufacturers:

7.1 Increased Operational Efficiency

With its high screening efficiency and customizable settings, the ZDS Vibrating Screen streamlines operations, leading to increased productivity and reduced operational costs.

7.2 Enhanced Product Quality

By ensuring precise material separation, the ZDS Vibrating Screen contributes to higher product quality, reducing the likelihood of defects and returns.

7.3 Lower Maintenance Costs

The durable construction of the ZDS Vibrating Screen means less frequent repairs and maintenance, translating to cost savings in the long run.

7.4 Environmental Responsibility

Utilizing the ZDS Vibrating Screen supports environmentally friendly practices by improving recycling rates and reducing waste.

8. ZDS Vibrating Screen vs. Traditional Material Separation Methods

When comparing the ZDS Vibrating Screen to traditional material separation methods, the advantages become apparent:

8.1 Efficiency Comparison

Traditional methods often struggle with high volumes and varied materials, leading to inefficiencies. The ZDS Vibrating Screen, on the other hand, handles diverse materials with ease, enhancing overall performance.

8.2 Cost-Effectiveness

While traditional methods may require extensive manual labor and frequent maintenance, the ZDS Vibrating Screen’s automated features reduce labor costs and downtime.

8.3 Quality of Separation

The precision of the ZDS Vibrating Screen ensures higher quality separation, reducing contamination risks and improving the integrity of the end products.

9. Conclusion

The ZDS Vibrating Screen stands out as a revolutionary tool that significantly enhances material separation in various manufacturing processes. Its unique features, versatility, and numerous benefits make it an indispensable asset for industries seeking to improve efficiency, quality, and sustainability. By investing in the ZDS Vibrating Screen, manufacturers can unlock new levels of productivity and operational excellence, positioning themselves for success in an increasingly competitive market.

10. FAQs

10.1 What materials can the ZDS Vibrating Screen separate?

The ZDS Vibrating Screen is capable of separating a wide range of materials, including minerals, metals, plastics, and organic materials, making it suitable for various industries.

10.2 How does the adjustable frequency feature work?

The adjustable frequency feature allows operators to modify the vibration settings to suit the specific characteristics of the materials being processed, optimizing separation efficiency.

10.3 What industries benefit most from ZDS Vibrating Screen technology?

Industries such as mining, recycling, food processing, and construction significantly benefit from the ZDS Vibrating Screen due to its efficiency and precision in material separation.

10.4 Is the ZDS Vibrating Screen easy to maintain?

Yes, the ZDS Vibrating Screen is designed for durability and ease of maintenance, resulting in lower operational costs and minimal downtime.

10.5 How can I determine if the ZDS Vibrating Screen is right for my operation?

Consider factors such as the volume and type of materials you process, your current separation methods, and the specific needs of your operation to assess whether the ZDS Vibrating Screen is a suitable investment.