Fertilizer Production Line

Bio-organic Fertilizer Production Line

Category:

E-mail:

Annual production line of 30,000-200,000 tons of bio-organic fertilizer

Production capacity

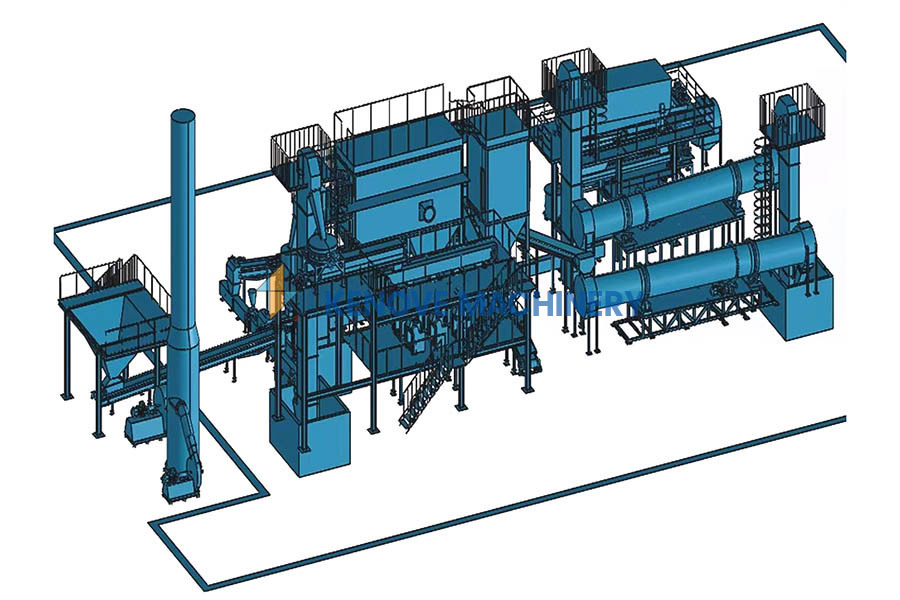

The production scale of this production line can be adjusted between 30,000 and 200,000 tons per year, which can meet the demands of enterprises with different production scales. The output can be flexibly adjusted according to market demand and the development plans of enterprises.

Main equipment

- Raw material pretreatment equipment: including crushers, screeners, etc., is used to crush and screen raw materials such as straw and livestock and poultry manure, remove impurities, and make them reach the appropriate particle size and moisture content, which is convenient for subsequent fermentation.

- Fermentation equipment: Common types include trough-type fermentation tanks and tower-type fermentation tanks, etc. During the fermentation process, by adding microbial agents, the decomposition effect of microorganisms is utilized to make the raw materials mature and ferment, and transform them into organic fertilizers.

- Deodorization equipment: such as biological deodorization towers, activated carbon adsorption devices, etc., are used to treat the odors produced during the fermentation process and reduce environmental pollution.

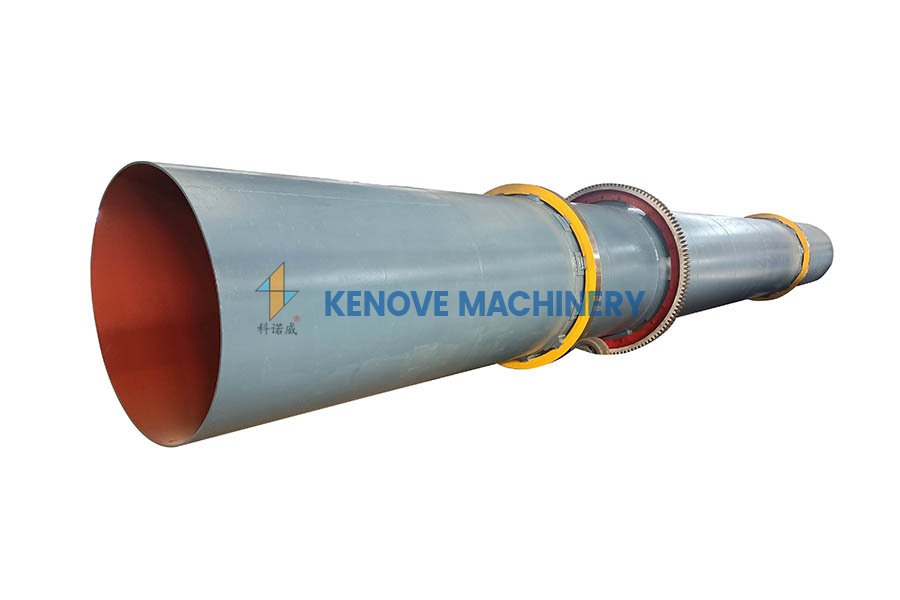

- Granulation equipment: There are disc granulators,rotary drum granulator,extrusion granulators, etc., which can turn the fermented materials into granules, making them convenient for packaging, transportation and application.

- Drying equipment: Rotary dryers are usually adopted. Through heat exchange, the moisture in the particles is removed to make the product meet the specified moisture content standard.

- Cooling equipment: Generally, cooling rollers are used to cool the dried particles, facilitating subsequent screening and packaging.

- Screening equipment: such as vibrating screens, which classify particles by particle size. Qualified particles are treated as finished products, while unqualified ones are returned for reprocessing.

- Packaging equipment: including automatic weighing scales, sealing machines, etc., to achieve automatic measurement and packaging of products.

Technological process

- Raw material collection and pretreatment: Collect organic waste and conduct pretreatment such as crushing, screening and humidity regulation.

- Fermentation and maturation: The pre-treated raw materials are mixed with microbial agents and placed in fermentation equipment for fermentation. After a period of aerobic or anaerobic fermentation, the raw materials are fully matured.

- Deodorization treatment: The odors produced during the fermentation process are treated by deodorization equipment and then discharged up to standard.

- Granulation: The fermented materials are fed into the granulator for granulation.

- Drying and cooling: After the particles are dried by the drying equipment, they are then cooled by the cooling equipment.

- Screening and packaging: After cooling, the particles are screened. Qualified products are packaged, while unqualified particles are returned to the relevant process for reprocessing.

Technical characteristics

- Wide range of raw materials: Various organic wastes can be used as raw materials to achieve resource recycling and reduce environmental pollution.

- Excellent product quality: Through fermentation and strict production process control, the product is rich in organic matter, beneficial microorganisms and various nutrients. It has a long-lasting fertilizer effect and can improve soil structure.

- Environmental protection and energy conservation: Equipped with deodorization and waste gas treatment systems to reduce odors and pollutant emissions. Meanwhile, part of the heat generated during the fermentation process can be recycled and utilized, reducing energy consumption.

- High degree of automation: By adopting an automated control system, it realizes the automated operation of raw material transportation, fermentation parameter control, granulation, drying and other links, improving production efficiency and product quality stability.

key word:

SHIPPMENT DISPLAY

Application Case

WHY CHOOSE US

Less manufacturing experience, less than 10 years

Not a high-tech enterprise, outdated technology.

The market share of fertilizer equipment in China less than 1%.

No R&D team

No Investment

No Patents and property rights

The quality of the raw materials is not good.

The material thickness is very thin.

The lifespan is shorter.

Annual production of over 11000+

Equipment production bases

Professional technical R&D team

Over 300 types of products

FAQ