Fertilizer Production Line

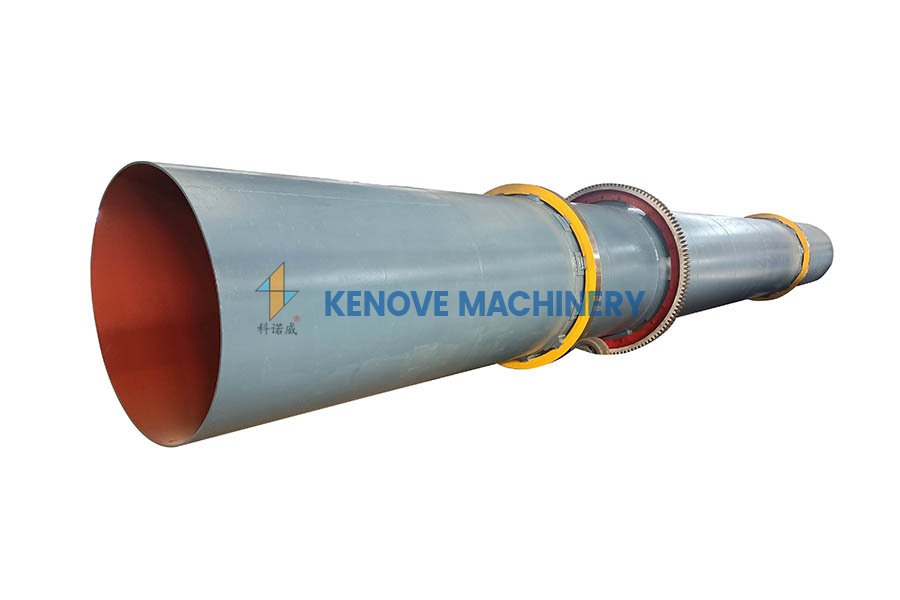

Rotary Cooler

Category:

E-mail:

| Model | Ф1.2X12 | Ф1.6X16 | Ф2.0X20 | Ф2.4X24 | Ф2.8X26 | Ф3.0X26 | Ф3.2X26 |

| Diameter x length (m) | 1.2x12 | 1.6x16 | 2.0x20 | 2.4x24 | 2.8x26 | 3.0x26 | 3.2x26 |

| Capacity (Tons/Hour) | 3-5 | 6-7 | 12-14 | 17-20 | 25-30 | 30-32 | 33-35 |

| Power (KW) | 7.5 | 18.5 | 30 | 55 | 90 | 110 | 132 |

| Installation Angle | 3.5% | 3.5% | 4% | 4% | 4% | 4% | 4% |

| Outlet air temperature | 50-70℃ | 50-70℃ | 50-70℃ | 50-70℃ | 50-70℃ | 50-90℃ | 50-70℃ |

In the production of fertilizer, the main function of the cooler machine is to reduce the temperature of the fertilizer particles.

To be specific:

1. Quality assurance: After the high-temperature fertilizer particles are cooled, the physical and chemical properties are more stable, reducing the risk of caking and nutrient loss, so as to ensure the quality and fertilizer efficiency of fertilizers.

2.Convenient for subsequent treatment:Reducing the temperature is conducive to the subsequent packaging process and avoiding adverse effects of high temperature on packaging materials, such as deformation and aging.

3.Safe production: Cooling can reduce the surface temperature of fertilizer particles, reducing the possibility of fire or explosion during storage and transportation.

4.Improve storage stability: the cooled fertilizer particles are not easy to absorb moisture and caking during storage, extending the storage period.

key word:

Rotary Equipment

SHIPPMENT DISPLAY

Application Case

WHY CHOOSE US

Less manufacturing experience, less than 10 years

Not a high-tech enterprise, outdated technology.

The market share of fertilizer equipment in China less than 1%.

No R&D team

No Investment

No Patents and property rights

The quality of the raw materials is not good.

The material thickness is very thin.

The lifespan is shorter.

Annual production of over 11000+

Equipment production bases

Professional technical R&D team

Over 300 types of products

FAQ