Fertilizer Production Line

Disc Pan Granulator

Category:

E-mail:

| Model | ZL18 | ZL20 | ZL22 | ZL25 | ZL30 | ZL32 |

| Diameter (mm) | 1800 | 2000 | 2200 | 2500 | 3000 | 3200 |

| Disc Height (mm) | 300 | 300 | 350 | 350 | 400 | 500 |

| Disc Angles | 40-55° | 40-55° | 40-55° | 40-55° | 40-55° | 40-55° |

| Rotate Speed (r/min) | 18 | 18 | 15 | 15 | 12 | 11 |

| Capacity (Tons/Hour) | 1.5-2 | 2-4 | 4-5 | 5-6 | 8-10 | 10-12 |

| Power (KW) | 4 | 5.5 | 5.5 | 7.5 | 11 | 15 |

Structure composition

Granulation plate part: the overall circular arc structure, the plate is lined with high-strength glass steel, the bottom of the plate is strengthened by radiation steel plate, composed of the disk body and disk joint, the disk joint can be adjusted up and down, the end side flange can protect the material ball.

Transmission part: the main motor drives the pulley and belt, and the pinion is driven by the reducer. The pinion meshes with the big gear fixed at the bottom of the disk to drive the pelleting disk.

Frame part: welded with high-quality channel steel, used to support the transmission part and rotation part of the whole body.

Adjustment part: welded by superior carbon steel plate and channel steel, used to install the granulation disk, can adjust the Angle of the granulation disk.

Scraper part: including non-power combination scraper, Angle scraper, etc., used to clean the edge, clean the bottom, clean the Angle, to prevent the material sticking to the wall.

Working principle: All kinds of dry powder materials are added from the top of the equipment, degassed, spiral pre-compressed and transported to the roll for forced compression, the compressed material naturally comes out, enters the crusher and the granulator for crushing and dressing, and then is screened by the vibrating screen, the qualified product is sent to the finished product warehouse or directly packaged, and the material under the screen is returned for secondary roll pressing. In the process of granulation, the material in the disc is bonded and wrapped into pellets by the sprayed adhesive. As the disc rotates, the particles gradually grow, the large particles flow out from below the disc, and the small particles continue to increase.

Features and Advantages

Reasonable structure design: novel structure, weight reduction, height reduction, flexible process layout, adjustable tilt Angle, using Angle gasket, easy to adjust.

Good granulation effect: the granulation rate can reach more than 93%, the diameter of the ball is 90% in 3-5mm, the granulation is uniform, the return grain is less, and the particles with high sphericity and uniform particle size can be produced.

Stable and reliable operation: the reducer and motor are driven by flexible belt, stable starting, durable, long service life, no anchor bolt fixing, stable operation.

Low power consumption: with a unique unpowered combined scraper integrated design, auxiliary power consumption is reduced, the large plate is composed of disk body and disk segment, which can reduce the power of the main motor.

Wide adaptability of raw materials: It can be used for granulation of various raw materials such as compound fertilizer, medicine, chemical industry, feed, coal, metallurgy, etc., and can produce various concentrations and types of compound fertilizer.

Application field: Widely used in the pelletizing production of bio-organic fertilizer, compound fertilizer, slow-release fertilizer and other fertilizers; It is also suitable for granulation of ceramisite sand, non-ferrous mineral powder and other materials, for preparing building materials, refractory materials, etc. In the pharmaceutical industry, the drug powder can be made into granules to facilitate the production, storage and administration of drugs; It can also be used for granulation of food additives, feed additives, etc.

key word:

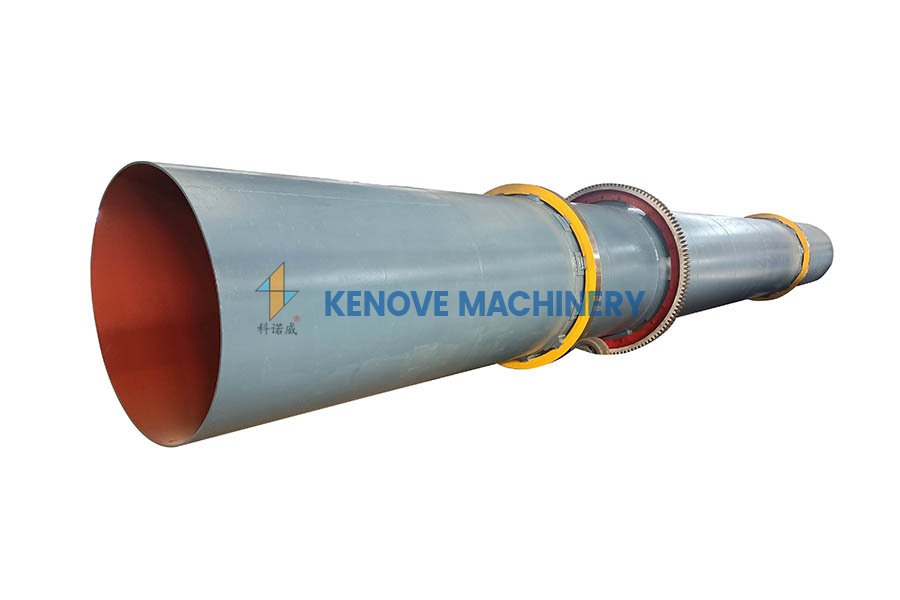

Rotary Equipment

SHIPPMENT DISPLAY

Application Case

WHY CHOOSE US

Less manufacturing experience, less than 10 years

Not a high-tech enterprise, outdated technology.

The market share of fertilizer equipment in China less than 1%.

No R&D team

No Investment

No Patents and property rights

The quality of the raw materials is not good.

The material thickness is very thin.

The lifespan is shorter.

Annual production of over 11000+

Equipment production bases

Professional technical R&D team

Over 300 types of products

FAQ