Fertilizer Production Line

Extrusion Granulation Compound Fertilizer Production Line

E-mail:

Fertilizer extrusion granulation production lines with an annual output of 50,000 to 1.2 million tons

Production capacity

This production line has a wide range of production capacity, capable of achieving an annual fertilizer production of 50,000 to 1.2 million tons, which can meet the production demands of enterprises of different scales.

Main equipment

- Raw material processing equipment: including crushers, pulverizers, etc., is used to break and crush blocky or large-grained raw materials into appropriate particle size for subsequent processing.

- Batching system: The proportion of various raw materials is precisely measured through electronic scales and other equipment to ensure the stability of product quality.

- Extrusion granulator: It is the core equipment of the production line. By applying pressure to the mixed raw materials, it turns them into granular form. Common types include flat die extrusion granulators and ring die extrusion granulators, etc.

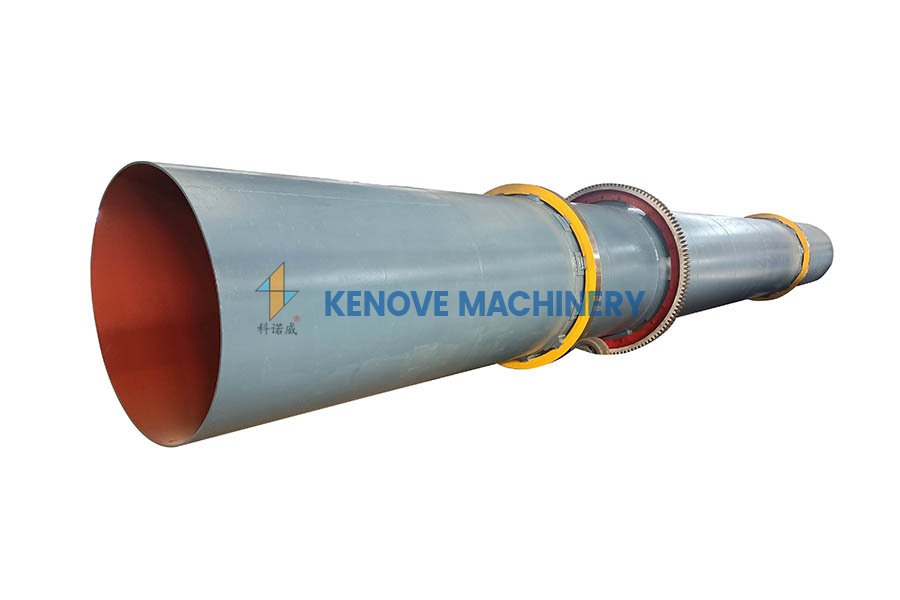

- Drying equipment: such as rotary dryers, which use hot air to dry the granulated fertilizer particles, reduce moisture content, and improve the stability and storability of the product.

- Cooling equipment: Counter-flow coolers are usually adopted to cool the dried particles to room temperature, facilitating subsequent screening and packaging.

- Screening equipment: Particles are screened through equipment such as vibrating screens. Those that do not meet the particle size requirements are screened out and returned for re-granulation or other processing.

- Coating equipment: It can apply a protective film on the surface of fertilizer particles, such as paraffin, resin, etc., to enhance the wear resistance and moisture resistance of the particles.

Technological process

- Raw material preparation: Prepare various fertilizer raw materials in a certain proportion and conduct pre-treatment, such as crushing and drying.

- Ingredient mixing: According to the product formula, the pre-treated raw materials are precisely measured through the ingredient system and then sent into the mixer for thorough mixing.

- Extrusion granulation: The well-mixed raw materials enter the extrusion granulator and form granules under pressure.

- Drying and cooling: After granulation, the granules enter the drying equipment for drying and then enter the cooling equipment for cooling.

- Screening and packaging: The cooled particles are screened by screening equipment. The qualified particles are packaged, while the unqualified ones are returned for reprocessing.

Technical characteristics

- Mature process: After years of development and practice, the fertilizer extrusion granulation technology has become quite mature, with a stable production process and reliable product quality.

- Strong adaptability: It can process a variety of different fertilizer raw materials and produce various types of fertilizer products, such as compound fertilizers and organic fertilizers.

- Good particle quality: The produced fertilizer particles have high strength and uniformity, which is conducive to fertilization and storage.

- Environmental protection and energy conservation: Advanced drying and dust removal technologies are adopted to reduce exhaust emissions and dust pollution. At the same time, energy conservation is emphasized in equipment selection and process design to lower production costs.

key word:

SHIPPMENT DISPLAY

Application Case

WHY CHOOSE US

Less manufacturing experience, less than 10 years

Not a high-tech enterprise, outdated technology.

The market share of fertilizer equipment in China less than 1%.

No R&D team

No Investment

No Patents and property rights

The quality of the raw materials is not good.

The material thickness is very thin.

The lifespan is shorter.

Annual production of over 11000+

Equipment production bases

Professional technical R&D team

Over 300 types of products

FAQ