Fertilizer Production Line

Rotary Drum Granulation Compound Fertilizer Production Line

E-mail:

Annual production capacity of 30,000-600,000 tons of fertilizer drum granulation production line

Production capacity

The production capacity of this production line can be adjusted between 30,000 tons and 600,000 tons per year, which can meet the production needs of enterprises of different scales. It has a certain degree of flexibility and can flexibly adjust the output according to market demand.

Main equipment

- Raw material supply equipment: including raw material silos, feeders, etc., which are used for storing and quantitatively supplying various basic fertilizer raw materials to ensure the continuity of production.

- Metering and batching system: Composed of electronic scales and other equipment, it accurately measures the input of various raw materials to ensure that the nutrient content of compound fertilizers meets the formula requirements.

- Mixing equipment: Common types include horizontal mixers or double-shaft paddle mixers, which thoroughly blend various raw materials to ensure uniform distribution of nutrients.

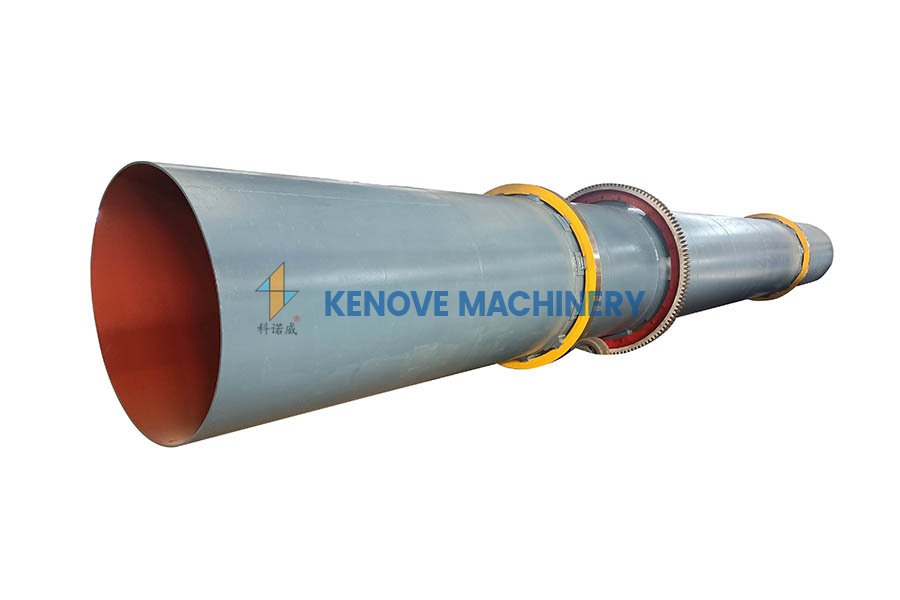

- Drum granulator: It is the core equipment of the production line, composed of components such as the drum, nozzle, and scraper. During the rotation of the drum, adhesive or water is sprayed onto the materials through nozzles, causing the materials to agglomerate into granules as they roll.

- Drying equipment: Rotary dryers are usually adopted, which use hot flue gas to dry wet particles, reducing the moisture content of the particles and improving product quality.

- Cooling equipment: Generally, counter-flow coolers are used to cool the dried particles to room temperature, facilitating subsequent screening and packaging.

- Screening equipment: such as vibrating screens, are used to screen particles. Particles that meet the particle size requirements are processed as finished products, while those that do not are returned for re-granulation or other treatments.

- Coating equipment: A coating machine is used to apply a protective film, such as anti-caking agent, on the surface of the particles to enhance the storage and transportation performance of the product.

Technological process

- Raw material preparation: Pre-treat various raw materials as required, such as crushing and drying, and then send them to the raw material warehouse for future use.

- Ingredient mixing: According to the product formula, various raw materials are accurately weighed through the metering and ingredient mixing system and sent into the mixing equipment for thorough mixing.

- Drum granulation: The mixed materials enter the drum granulator. Under the rotation of the drum, the materials are gradually agglomerated into granules by spraying binders or water.

- Drying and cooling: The wet granules after granulation enter the drying equipment for drying and then enter the cooling equipment for cooling.

- Screening and packaging: After cooling, the particles are screened by screening equipment. Qualified particles are coated and packaged as finished products, while unqualified particles are returned to the corresponding process for reprocessing.

Technical characteristics

- Mature and stable process: After years of development and practice, the drum granulation technology has a mature process, a stable and reliable production process, and is easy to operate and control.

- Strong adaptability to raw materials: It can process a variety of different raw materials, including urea, ammonium phosphate, potassium fertilizer, etc., and is capable of producing compound fertilizers with multiple formulas.

- Good particle quality: The produced particles have a relatively regular shape and moderate strength, which is conducive to fertilization and storage.

- Convenient equipment maintenance: The main equipment such as the drum granulator has a relatively simple structure, making maintenance and upkeep convenient, which can reduce equipment repair costs and downtime.

key word:

SHIPPMENT DISPLAY

Application Case

WHY CHOOSE US

Less manufacturing experience, less than 10 years

Not a high-tech enterprise, outdated technology.

The market share of fertilizer equipment in China less than 1%.

No R&D team

No Investment

No Patents and property rights

The quality of the raw materials is not good.

The material thickness is very thin.

The lifespan is shorter.

Annual production of over 11000+

Equipment production bases

Professional technical R&D team

Over 300 types of products

FAQ