Fertilizer Production Line

Water-soluble Fertilizer Production Line

Category:

E-mail:

Production line of water-soluble fertilizer with an annual output of 10,000 to 100,000 tons

Production capacity

The production scale of this production line can vary between 10,000 and 100,000 tons per year. It can be flexibly adjusted according to market demand and the actual situation of the enterprise, and is suitable for water-soluble fertilizer production enterprises of different scales.

Main equipment

- Raw material storage system: Composed of multiple storage tanks and silos, it is used to store various water-soluble raw materials, such as potassium nitrate, potassium dihydrogen phosphate, trace elements, etc. Each storage container is equipped with an accurate metering device, which can precisely control the amount of raw materials added.

- Batching system: High-precision electronic scales are used for the measurement and batching of raw materials. Automated operation is achieved through a computer control system. Various raw materials can be precisely weighed according to the preset formula to ensure the accuracy of the nutrient content of the product.

- Mixing system: Usually, high-efficiency helical ribbon mixers or plow blade mixers are used, which can thoroughly and evenly mix various raw materials in a short time, ensuring the quality stability of water-soluble fertilizers.

- Reaction system: For the production of water-soluble fertilizers that require chemical reactions, a reaction vessel is equipped, which can precisely control parameters such as reaction temperature, time, and pH value to ensure that the reaction proceeds fully.

- Granulation system: According to product requirements, spray drying granulators, disc granulators or extrusion granulators, etc. can be selected to make the mixed or reacted materials into granular form, improving the solubility and physical properties of the product.

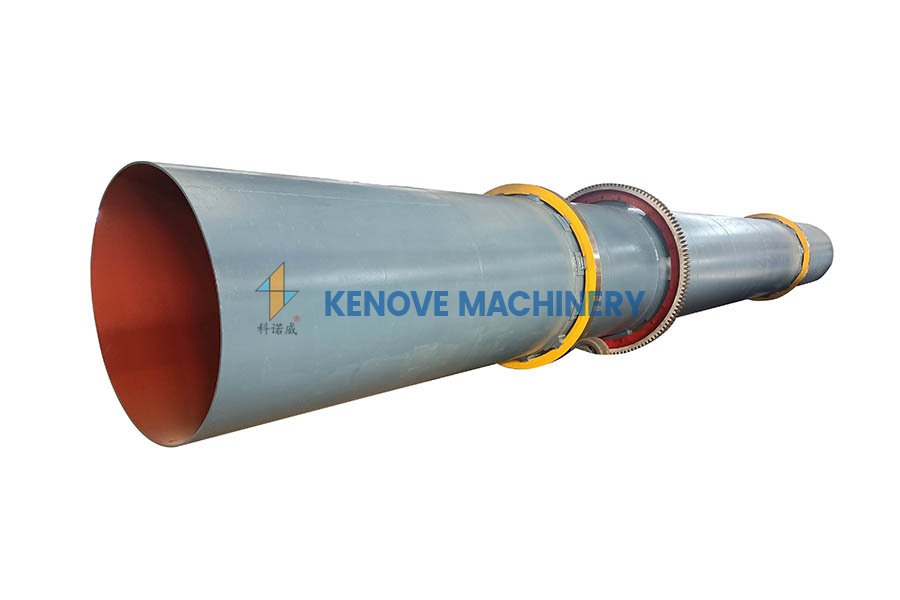

- Drying system: Equipment such as fluidized bed dryers or air flow dryers are used to dry wet particles, remove moisture, and make the product meet the specified moisture content standard, which is convenient for storage and transportation.

- Screening system: Such as vibrating screens, which classify particles by particle size, screen out the finished particles that meet the requirements, and return the unqualified particles for reprocessing.

- Packaging system: It includes automatic packaging scales, sealing machines and other equipment, which can achieve automatic measurement and packaging of water-soluble fertilizers, improving packaging efficiency and accuracy.

Technological process

- Raw material preparation: Store various water-soluble raw materials in the raw material storage system as required for pretreatment, such as crushing and dissolving.

- Ingredient mixing: According to the product formula, the raw materials are precisely weighed through the ingredient system and sent into the mixing system for thorough mixing. For products with reaction requirements, reactions are carried out in the reaction system.

- Granulation and drying: The mixed or reacted materials enter the granulation system to form granules, and then are dried through the drying system.

- Screening and packaging: The dried particles are classified through the screening system, and the qualified finished products enter the packaging system for packaging.

Technical characteristics

- Flexible formula: Through the computer control system, the formula can be quickly adjusted to produce water-soluble fertilizers with different nutrient contents and functions, meeting the needs of various crops and different growth stages.

- High solubility: The production process is strictly controlled, resulting in uniform product particles and excellent solubility. It can quickly dissolve in water, facilitating absorption by crops.

- High degree of automation: From raw material batching, mixing, granulation to packaging and other links, automated operation has been achieved, reducing manual intervention and improving production efficiency and the stability of product quality.

- Environmental protection and energy conservation: Advanced drying technology and dust recovery devices are adopted, which reduces energy consumption and dust emissions, meeting environmental protection requirements.

key word:

SHIPPMENT DISPLAY

Application Case

WHY CHOOSE US

Less manufacturing experience, less than 10 years

Not a high-tech enterprise, outdated technology.

The market share of fertilizer equipment in China less than 1%.

No R&D team

No Investment

No Patents and property rights

The quality of the raw materials is not good.

The material thickness is very thin.

The lifespan is shorter.

Annual production of over 11000+

Equipment production bases

Professional technical R&D team

Over 300 types of products

FAQ