Fertilizer Production Line

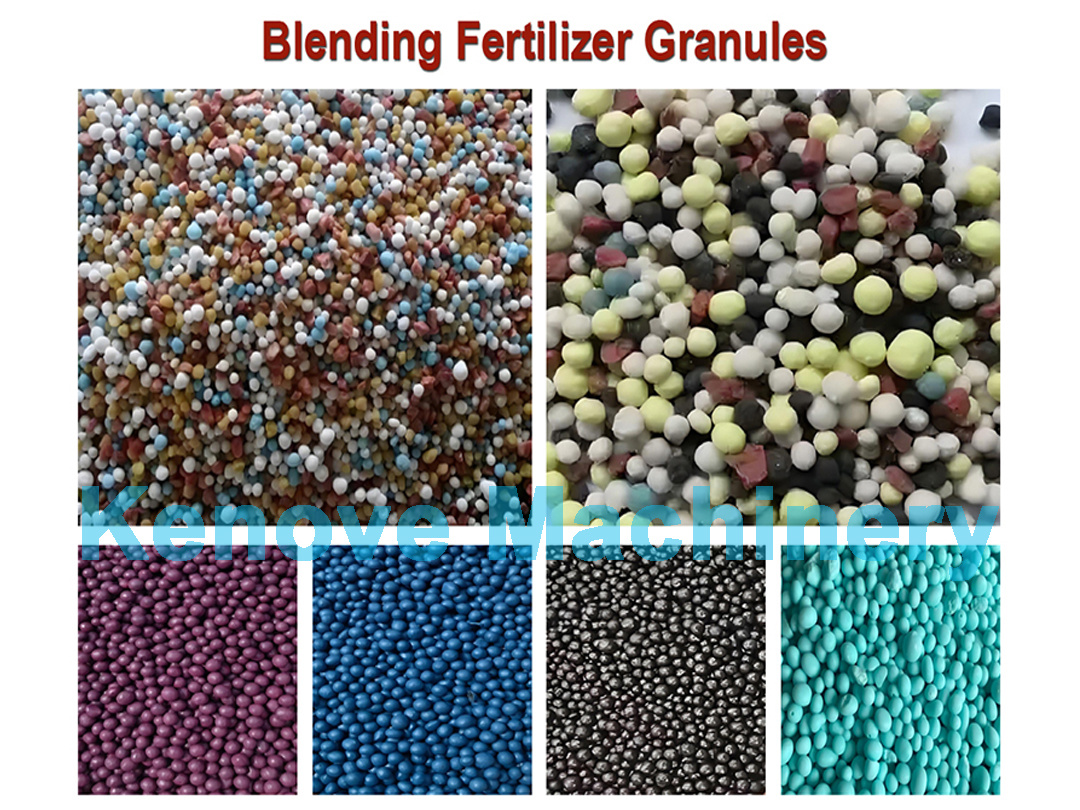

Blended / (BB) Fertilizer Production Line

E-mail:

Annual production capacity of 50,000-500,000 tons of automated blended fertilizer production line

Production capacity

The production capacity of this production line can be flexibly adjusted between 50,000 tons and 500,000 tons per year, which can meet the production demands of different scales. It can not only satisfy the production needs of small enterprises but also handle larger-scale order production tasks.

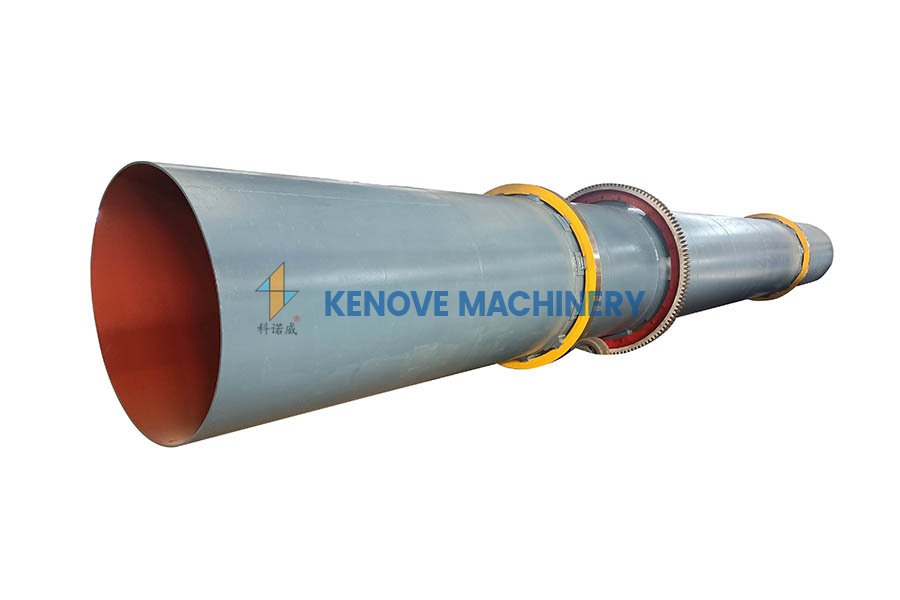

Main equipment

- Raw material storage system: Composed of multiple raw material silos, it is used to store different types and specifications of basic fertilizer raw materials. Each raw material silo is equipped with a corresponding feeding device, which can precisely control the output of raw materials.

- Batching system: High-precision electronic scales are used to precisely measure various raw materials. Through a computer control system, automated batching is achieved to ensure that each raw material is accurately proportioned according to the set formula.

- Mixing system: Usually, high-efficiency mixing equipment such as double-shaft paddle mixers or V-type mixers are adopted, which can thoroughly and evenly mix various raw materials in a short time, ensuring the stability of product quality.

- Packaging system: It includes automatic packaging scales, sewing machines and other equipment, which can achieve automatic measurement and packaging of fertilizers, improve packaging efficiency and accuracy, and reduce manual operation errors.

- Conveying system: Composed of belt conveyors, bucket elevators, etc., it is responsible for transporting raw materials from the storage area to the batching area, as well as the mixed finished products to the packaging area, achieving automated material conveying and enhancing production efficiency.

Technological process

- Raw material storage: Store various basic fertilizer raw materials separately in the corresponding raw material silos to ensure the quality of the raw materials and storage conditions.

- Automatic batching: According to the set formula, the computer control system controls the feeding devices and electronic scales in each raw material bin to accurately weigh the weight of various raw materials and complete the batching process.

- Uniform mixing: After the raw materials are mixed, they enter the mixer for thorough stirring and mixing to ensure that the nutrients in the fertilizer are evenly distributed.

- Finished product packaging: The mixed finished fertilizer is conveyed to the packaging area through the conveying system, measured and packaged by the automatic packaging scale, and then sealed by the sewing machine to become the finished product.

Technical characteristics

- High degree of automation: By adopting a computer control system, the entire process from raw material batching, mixing to packaging has been fully automated, reducing manual intervention and enhancing production efficiency and the stability of product quality.

- Flexible formula: According to different market demands and crop nutrient requirements, the fertilizer formula can be quickly adjusted. Just input new formula parameters in the control system, and the production of blended fertilizers with different formulas can be achieved.

- Precise measurement: High-precision electronic scales and advanced batching control technology ensure the accuracy of raw material batching, making the nutrient content of the product meet the standard requirements and keeping the error within a very small range.

- Environmental protection and energy conservation: During the production process, emphasis is placed on dust collection and treatment, which reduces dust emissions and lowers environmental pollution. Meanwhile, the reasonable selection and optimized design of the equipment have reduced energy consumption and achieved energy-saving production.

key word:

SHIPPMENT DISPLAY

Application Case

WHY CHOOSE US

Less manufacturing experience, less than 10 years

Not a high-tech enterprise, outdated technology.

The market share of fertilizer equipment in China less than 1%.

No R&D team

No Investment

No Patents and property rights

The quality of the raw materials is not good.

The material thickness is very thin.

The lifespan is shorter.

Annual production of over 11000+

Equipment production bases

Professional technical R&D team

Over 300 types of products

FAQ