Fertilizer Production Line

High Tower Granulation Compound Fertilizer Production Line

E-mail:

High-tower granulation production line for compound fertilizer with an annual output of 100,000 to 600,000 tons

Production capacity

The production capacity of this production line can be adjusted between 100,000 tons and 600,000 tons per year, which can meet the demands of compound fertilizer production enterprises of different scales and has a certain degree of flexibility and scalability.

Main equipment

- Raw material storage and conveying equipment: including various raw material silos and belt conveyors, etc., which are used for storing and conveying all kinds of basic fertilizer raw materials to ensure the continuous supply of production.

- Metering and batching system: Composed of electronic metering scales, etc., it precisely controls the proportion of various raw materials to ensure the accuracy and stability of the nutrient content of compound fertilizers.

- Mixing equipment: such as a double-shaft paddle mixer, which thoroughly mixes the proportionally prepared raw materials evenly to prepare for subsequent granulation.

- Melting system: For raw materials that need to be melted, such as urea, etc., they are made to reach a molten state through melting tanks, steam heating devices, etc., so as to better coat other raw materials during the granulation process.

- High tower granulation system: It is the core part of the production line, including granulation nozzles, high towers, etc. The molten material is sprayed out from the nozzles at the top of the tall tower. Under the action of gravity and air resistance, the droplets cool and solidify into particles and fall to the bottom of the tower.

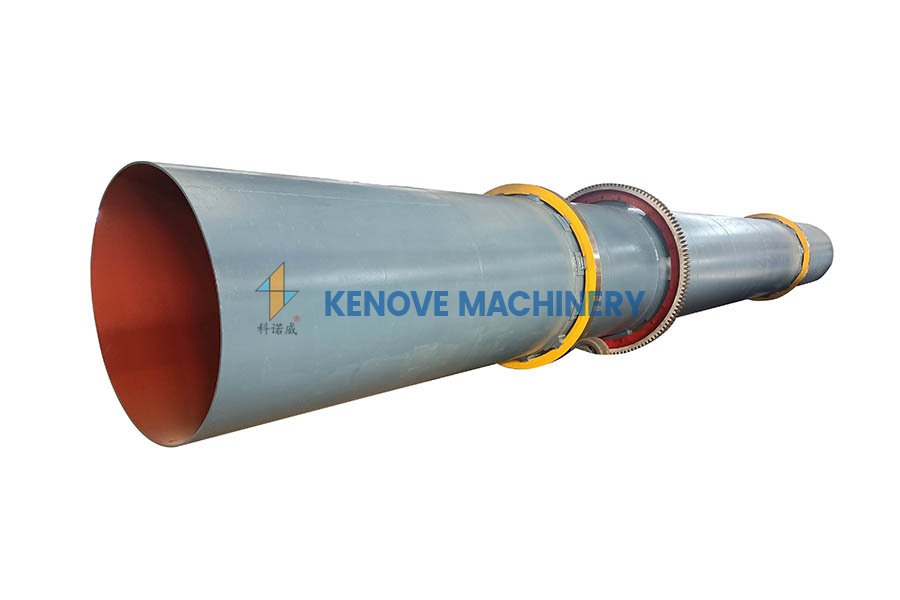

- Cooling and screening equipment: The particles are cooled by a cooling drum, and then classified by particle size through a vibrating screen. Qualified particles proceed to the next process, while unqualified ones are returned for reprocessing.

- Coating equipment: Usually, coating machines are used to apply anti-caking agents and other coating materials on the surface of the particles to enhance the storage and transportation performance of compound fertilizers.

Technological process

- Raw material pretreatment: Some raw materials are subjected to pretreatment such as crushing and drying to meet production requirements.

- Ingredient mixing: According to the product formula, various raw materials are accurately weighed through the metering and ingredient system and sent into the mixing equipment for thorough mixing.

- Melting and granulation: Some components of the mixed materials are melted and then granulated through nozzles at the top of the high tower. The liquid droplets cool and solidify into particles during their fall.

- Cooling and screening: After the particles are cooled, they are screened to grade products of different particle sizes.

- Coating and packaging: Qualified granules are coated and then packaged to become finished compound fertilizers.

Technical characteristics

- Excellent particle quality: The compound fertilizer particles produced by high tower granulation are spherical in shape, with a smooth surface, uniform particle size, high compressive strength and low moisture content, which is conducive to nutrient release and storage.

- Good nutrient uniformity: Through precise batching and mixing systems, as well as the method of granulation wrapped by molten droplets, various nutrients in the compound fertilizer are evenly distributed.

- High production efficiency: This production line has a high degree of automation and can achieve continuous production. Moreover, during the high tower granulation process, the material processing capacity is large, which can meet the requirements of high output.

- Good environmental protection performance: It adopts an advanced exhaust gas treatment system to purify the waste gas produced during the production process, reducing pollution to the environment. Meanwhile, high tower granulation itself is a relatively energy-efficient granulation process. Compared with some other granulation methods, its energy consumption is relatively low.

High Tower Granulation Compound Fertilizer Production Line is a modern and efficient solution for producing high-quality compound fertilizers. Using advanced tower granulation technology, this system ensures uniform granule size, strong hardness, and excellent solubility, which directly improves fertilizer effectiveness. With high automation and energy-saving design, it is widely adopted in large-scale fertilizer manufacturing.

This High Tower Granulation Compound Fertilizer Production Line offers stable operation and consistent product quality. The process includes raw material batching, high tower spraying, rapid cooling, and automatic packaging. Each step is precisely controlled to maintain nutrient balance in the final product. Its high granulation rate significantly reduces production loss, making it an ideal choice for fertilizer enterprises.

Compared with traditional methods, the High Tower Granulation Compound Fertilizer Production Line reduces dust emissions and environmental impact. Its compact structure and closed production process meet modern green manufacturing standards. The advanced spraying and cooling systems ensure that the granules have better moisture resistance and longer storage life.

In addition to efficiency and quality, the High Tower Granulation Compound Fertilizer Production Line also allows flexible formulation to meet different crop and soil requirements. It can produce a variety of NPK ratios and customized fertilizers for global agricultural demands. This production line not only improves enterprise competitiveness but also supports sustainable farming development worldwide.

key word:

SHIPPMENT DISPLAY

Application Case

WHY CHOOSE US

Less manufacturing experience, less than 10 years

Not a high-tech enterprise, outdated technology.

The market share of fertilizer equipment in China less than 1%.

No R&D team

No Investment

No Patents and property rights

The quality of the raw materials is not good.

The material thickness is very thin.

The lifespan is shorter.

Annual production of over 11000+

Equipment production bases

Professional technical R&D team

Over 300 types of products

FAQ