Fertilizer Production Line

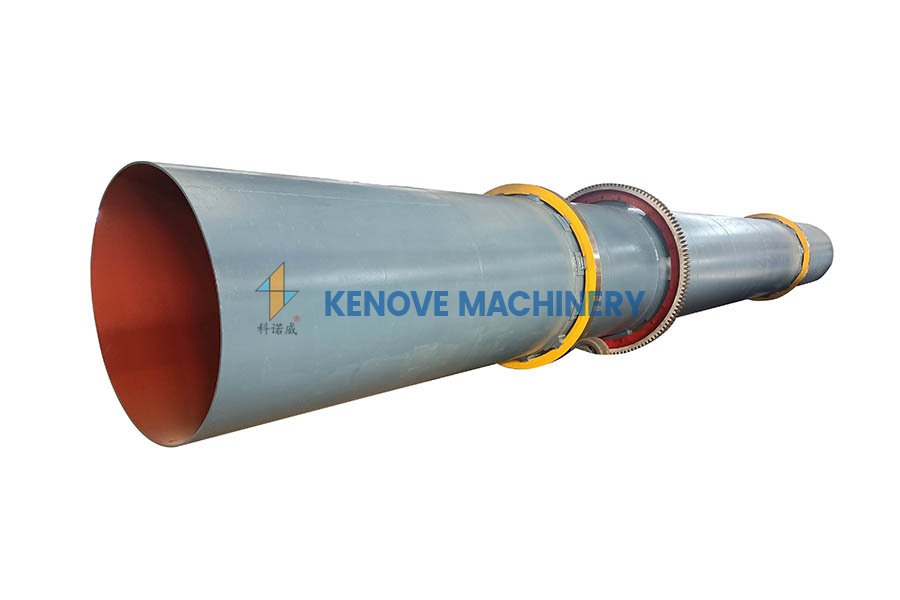

Rotary Drum Granulator

Category:

E-mail:

| Model | ZGJ1240 | ZGJ1450 | ZGJ1660 | ZGJ1870 | ZGJ2080 | ZGJ2280 |

| Capacity(t/h) | 1-3 | 3-5 | 5-8 | 8-10 | 8-15 | 15-20 |

| Power(kw) | 7.5 | 11 | 15 | 22 | 30 | 37 |

| Inner diameter (mm) | 1200 | 1400 | 1600 | 1800 | 2000 | 2200 |

| Length (mm) | 4000 | 5000 | 6000 | 7000 | 8000 | 8000 |

| Rotate speed (r/min) | 17 | 14 | 11.5 | 11.5 | 11 | 10.5 |

| Installation Angle(°) | 2-5 | 2-5 | 2-5 | 2-5 | 2-5 | 2-5 |

| Finished particle size(mm) | 1-5 | 2%-5% | 2%-5% | 2%-5% | 2%-5% | 2%-5% |

The role of granulator in fertilizer production is mainly to process powdered or fine granular raw materials into granular products with a certain shape, size and strength.

Specifically, the granulator has the following important roles:

1.Improve physical properties: After the material is formed into particles, it has better fluidity, permeability and packing density, which is easy to store, transport and use.

2.Improve product quality: help to control the release speed and uniformity of nutrients in fertilizers,improve the utilization rate and fertilizer efficiency of fertilizers.

3. Increase product stability: compared with powdery materials, granular products are less prone to hygroscopic agglomeration, better chemical stability, and longer storage life.

4. Easy to measure and apply: the particle size is uniform, easy to accurately measure and evenly spread, and reduce the error in the fertilization process.

5. Reduce dust pollution: reduce the dust flying during the handling and use of powdery materials, which is more friendly to the environment and operators.

6. Enhance market competitiveness: granular fertilizer products with good appearance and stable quality are more favored in the market, which helps to improve the competitiveness of enterprises.

The rotary drum agglomerator is a versatile and robust machine designed to transform fine powders and granules into uniform, free-flowing agglomerates. Ideal for industries such as mining, fertilizers, and chemical processing, this equipment ensures consistent particle size and improved material handling. The rotary drum agglomerator utilizes a tumbling motion combined with binder spray systems to create dense, spherical pellets. Its large processing capacity and adaptability make it a preferred solution for high-volume production lines.

Engineered for durability, the rotary drum agglomerator features a heavy-duty steel drum with abrasion-resistant linings, ensuring long service life even under harsh conditions. The adjustable rotation speed and tilt angle allow precise control over agglomeration time and pellet size. Integrated spray nozzles evenly distribute liquid binders, optimizing moisture content for superior pellet formation. Whether processing fertilizers, ores, or industrial powders, this machine delivers high efficiency with minimal energy consumption.

The rotary drum agglomerator is designed for easy integration into existing production lines, with options for custom sizing and automation. Advanced control systems monitor drum speed, binder flow, and temperature, ensuring consistent product quality. Dust collection and exhaust systems maintain a clean working environment, reducing waste and improving operator safety. Its low-maintenance design minimizes downtime, making it a cost-effective solution for continuous agglomeration processes.

Choosing a rotary drum agglomerator enhances product uniformity, reduces dust-related losses, and improves downstream processing efficiency. Its robust construction and customizable features make it suitable for a wide range of materials and industrial applications. Whether for granulation, coating, or conditioning, this machine ensures reliable performance and high output. Invest in a rotary drum agglomerator to optimize your bulk material processing with precision and efficiency.

key word:

Rotary Equipment

newest Rotary drum agglomerator

best Rotary drum pelletizer

newest Rotary drum coater

SHIPPMENT DISPLAY

Application Case

WHY CHOOSE US

Less manufacturing experience, less than 10 years

Not a high-tech enterprise, outdated technology.

The market share of fertilizer equipment in China less than 1%.

No R&D team

No Investment

No Patents and property rights

The quality of the raw materials is not good.

The material thickness is very thin.

The lifespan is shorter.

Annual production of over 11000+

Equipment production bases

Professional technical R&D team

Over 300 types of products

FAQ