Fertilizer Production Line

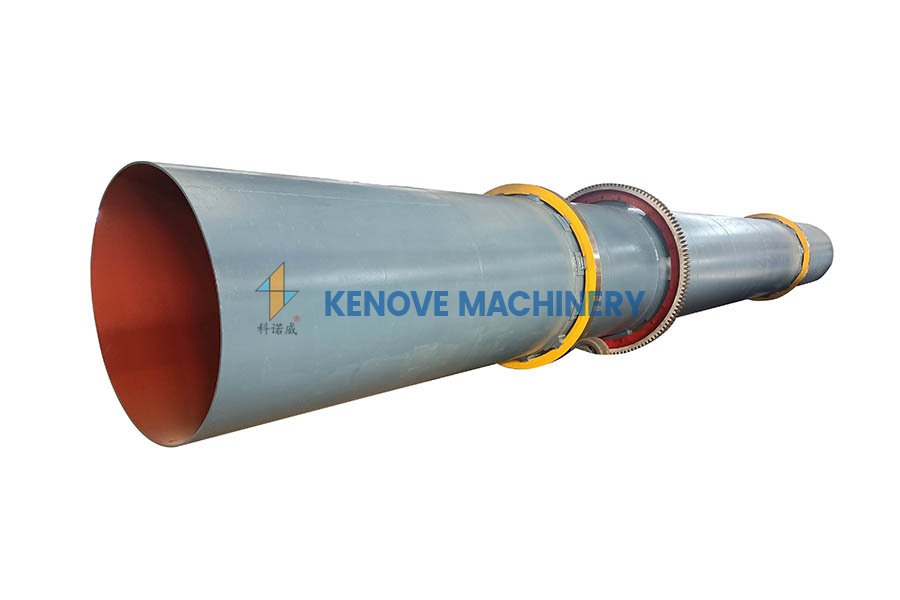

Coating Machine

Category:

E-mail:

| Model | Ф1.2X4 | Ф1.4X6 | Ф1.6X6 | Ф1.8X7 | Ф2.0X8 | Ф2.2X10 |

| Diameter x length (m) | 1.2x4 | 1.4x6 | 1.6x6 | 1.8x7 | 2.0x8 | 2.2x10 |

| Capacity (Tons/Hour) | 5-8 | 8-10 | 10-15 | 15-20 | 20-25 | 25-30 |

| Power (KW) | 5.5 | 7.5 | 11 | 15 | 18.5 | 22 |

| Installation Angle | 4% | 4% | 4% | 4% | 4% | 4% |

The role of the coating machine in related production is mainly to uniformly coat a film or coating on the surface of the material particles.

Taking fertilizer production as an example, the coating machine can form a coating on the surface of the fertilizer particles, and its functions include:

1.Control nutrient release:Through the characteristics and thickness of the envelope, control the release speed and release cycle of nutrients in fertilizers,achieve long-term and slow release effect,and improve the utilization rate of fertilizers.

2. Moisture and anti-caking: The formed coating can reduce the contact between fertilizer particles and the external environment (such as humidity), reduce the possibility of hygroscopic caking, and facilitate storage and transportation.

3.Improve the appearance: make the surface of fertilizer particles more smooth and uniform, improve the appearance quality of products.

4.Increase the function: for example, add the coating material with the function of insect prevention and disease prevention to give the fertilizer additional characteristics.

In other industries, such as pharmaceutical, food, etc., the coating machine also has a similar role, according to different products and needs, to achieve protection, modification,function enhancement and other purposes.

The Rotary Drum Coater represents a significant advancement in industrial coating technology. This robust system is engineered for uniform and efficient application of coatings, films, or active layers onto a wide variety of solid substrates, including powders, granules, and pellets. Its versatility makes it an indispensable asset for industries seeking to enhance product value through precise coating processes. The core of its design ensures consistent quality and repeatability in every batch.

At the heart of this machine's superior performance is its innovative drum design. The gently rotating drum provides a perfectly controlled environment for tumbling and mixing the product. A sophisticated spraying system, featuring precision nozzles, then delivers the coating solution as a fine, uniform mist. This meticulous integration ensures every particle receives an even coat, minimizing waste and maximizing product yield. The efficiency of this Rotary Drum Coater is unmatched in its class.

Operational efficiency and user control are paramount. The system is managed via an intuitive PLC interface, allowing operators to easily set and monitor critical parameters such as drum rotation speed, spray rate, air flow, and temperature. This high level of automation guarantees process consistency and simplifies scale-up from development to full production. The design of the Rotary Drum Coater prioritizes not just performance but also ease of use and maintenance.

Constructed from high-grade, corrosion-resistant materials, this coater is built for durability and longevity. It meets stringent international standards for quality and safety, making it a reliable and future-proof investment for pharmaceutical, food, chemical, and fertilizer sectors. By integrating this advanced Rotary Drum Coater into your production line, you significantly improve product quality, reduce operational costs, and gain a powerful competitive edge in the market.

key word:

Rotary Equipment

Quality Rotary Drum Coater

SHIPPMENT DISPLAY

Application Case

WHY CHOOSE US

Less manufacturing experience, less than 10 years

Not a high-tech enterprise, outdated technology.

The market share of fertilizer equipment in China less than 1%.

No R&D team

No Investment

No Patents and property rights

The quality of the raw materials is not good.

The material thickness is very thin.

The lifespan is shorter.

Annual production of over 11000+

Equipment production bases

Professional technical R&D team

Over 300 types of products

FAQ