Fertilizer Production Line

Urea Melting Tank

Category:

E-mail:

The urea melting tank produced by the factory heats the granular urea and converts it into urea liquid quickly by stirring, and the melting time is short, which fundamentally reduces the production of biuret. The device is made of stainless steel and has the characteristics of corrosion resistance, small footprint and long service life.

| Model | NR1010 | NR1012 | NR1212 | NR1215 | NR1512 | NR1515 | NR2016 | NR2020 |

| Diameter/mm | Φ1000 | Φ1200 | Φ1500 | Φ2000 | ||||

| Height/mm | 1000 | 1200 | 1200 | 1500 | 1200 | 1500 | 1600 | 2000 |

| Heating coil diameter /mm | Φ700/500 | Φ900/650 | Φ1100/800 | Φ1600/1100 | ||||

| Stirring blade speed r/min | 60-80 | |||||||

| Capacity Kg/h | 500 | 700 | 800 | 1000 | 1500 | 2000 | 3000 | 4000 |

| Power Kw | 3 | 4 | 3 | 4 | 7.5 | 11 | ||

The Urea Melting Tank is a specialized piece of equipment designed for the efficient melting and preparation of urea solutions, widely used in fertilizer production, chemical industries, and SCR (Selective Catalytic Reduction) systems for NOx emission control. With its advanced heating and mixing technology, the Urea Melting Tank ensures a consistent and uniform solution, improving process efficiency and product quality.

Constructed from high-grade, corrosion-resistant materials, the Urea Melting Tank is built for durability and long service life, even under demanding industrial conditions. Its optimized thermal system provides precise temperature control, preventing crystallization or decomposition of urea during the melting process. This guarantees stable performance and reduces energy consumption.

The design of the Urea Melting Tank emphasizes ease of use and maintenance. It features an insulated structure to minimize heat loss, an efficient agitation system to maintain uniformity, and user-friendly access points for cleaning and servicing. Safety systems are also integrated to ensure reliable and secure operation during continuous production.

Overall, the Urea Melting Tank is a cost-effective solution that supports high productivity, energy efficiency, and environmental compliance. Its robust construction, advanced functionality, and reliable performance make it an essential choice for modern fertilizer plants and industrial applications requiring stable urea solutions.

key word:

Urea azotization

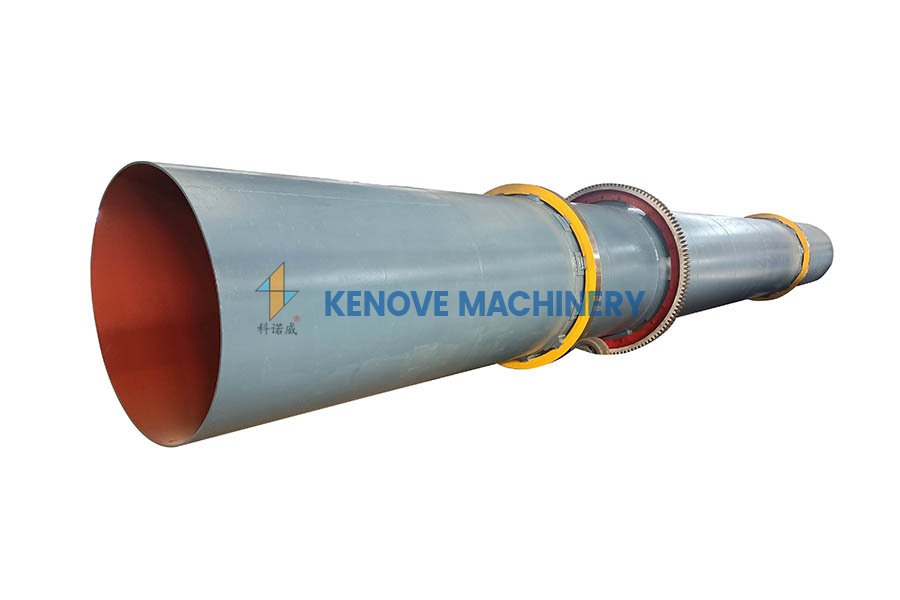

SHIPPMENT DISPLAY

Application Case

WHY CHOOSE US

Less manufacturing experience, less than 10 years

Not a high-tech enterprise, outdated technology.

The market share of fertilizer equipment in China less than 1%.

No R&D team

No Investment

No Patents and property rights

The quality of the raw materials is not good.

The material thickness is very thin.

The lifespan is shorter.

Annual production of over 11000+

Equipment production bases

Professional technical R&D team

Over 300 types of products

FAQ