Essential Features to Look for in a Disc Pan Granulator: Your Ultimate Guide

Release time:

Sep 01,2025

Essential Features to Look for in a Disc Pan Granulator In the agricultural machinery industry, the disc pan granulator stands out as a crucial tool for effective granulation processes. Whether you are working with fertilizers, animal feeds, or other agronomic products, understanding the essential features of a disc pan granulator can significantly enhance your production efficiency and product qu

Essential Features to Look for in a Disc Pan Granulator

In the agricultural machinery industry, the disc pan granulator stands out as a crucial tool for effective granulation processes. Whether you are working with fertilizers, animal feeds, or other agronomic products, understanding the essential features of a disc pan granulator can significantly enhance your production efficiency and product quality. This article will delve into key aspects that should guide your selection, ensuring that you choose the right equipment for your specific needs.

Table of Contents

- Understanding Disc Pan Granulators

- Key Features to Consider

- Design and Structure

- Size and Capacity

- Material Quality

- Motor and Power Requirements

- Adjustability and Control Systems

- Maintenance and Durability

- Energy Efficiency

- Cost Considerations

- Choosing the Right Manufacturer

- Conclusion

Understanding Disc Pan Granulators

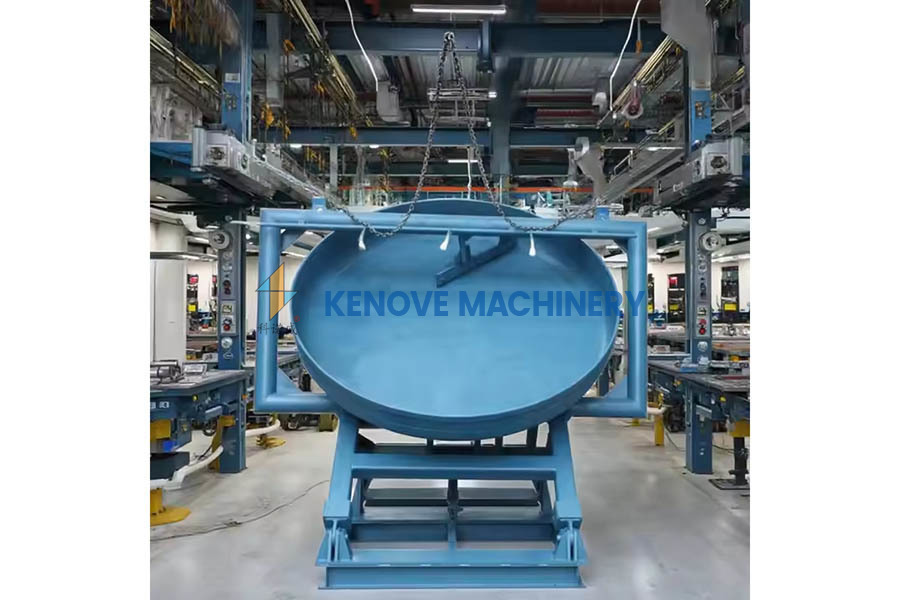

Disc pan granulators are widely used in the agricultural sector for producing granules from powdered materials. The granulation process involves the formation of small, round pellets, which are crucial for enhancing the solubility and effectiveness of fertilizers and feeds. The operation of a disc pan granulator typically revolves around the rotation of a pan-like disc that facilitates the mixing and agglomeration of materials.

This equipment is not just vital for granulating fertilizers but also plays an essential role in various industries such as pharmaceuticals and chemicals. Understanding their mechanics and application can greatly influence your operational efficiency and product quality.

Key Features to Consider

When selecting a disc pan granulator, several features must be evaluated to ensure it meets your specific operational requirements. Here, we will discuss some of the most important attributes to consider.

Design and Structure

The **design and structure** of a disc pan granulator play a pivotal role in its effectiveness. A robust and durable construction ensures longevity and consistent performance. Important design elements include:

- **Pan Diameter**: A larger diameter increases the granulator's capacity to produce more granules in a shorter time.

- **Angle of Inclination**: This affects the flow of materials within the granulator and can influence granule size.

- **Rim Height**: A higher rim prevents material spillage, ensuring a clean and efficient operation.

These design considerations will determine how well the granulator performs during high-capacity runs.

Size and Capacity

The **size and capacity** of your granulator should be aligned with your production demands. Evaluate the following:

- **Production Volume**: Consider how much material you need to process and select a granulator that can handle this volume efficiently.

- **Batch vs. Continuous Operation**: Determine whether you need a batch granulator for smaller tasks or a continuous one for larger, ongoing productions.

Choosing the right size will not only enhance your productivity but will also minimize energy consumption.

Material Quality

The **material quality** of the granulator is paramount. Look for equipment made from high-grade steel or other durable materials that can withstand the abrasive nature of the raw materials being processed. Key points to consider include:

- **Corrosion Resistance**: This is crucial for equipment that might be exposed to moisture or corrosive substances.

- **Wear Resistance**: Components that are prone to wear, such as the pan and blades, should be constructed from materials that can endure rigorous operational demands.

High-quality materials ensure that your granulator will have a longer lifespan and require less frequent repairs.

Motor and Power Requirements

The **motor and power requirements** of a disc pan granulator are critical for its operational efficiency. Consider the following aspects:

- **Power Rating**: A more powerful motor will typically handle larger volumes and denser materials more effectively. Evaluate the motor's horsepower (HP) in relation to your expected workload.

- **Energy Efficiency**: Look for granulators that offer energy-efficient motors to reduce operational costs and environmental impact.

Selecting the right motor will enhance performance while keeping operational costs manageable.

Adjustability and Control Systems

Modern disc pan granulators come equipped with various **adjustability and control systems** that enhance usability. Key features to consider include:

- **Speed Control**: Adjustable speed settings allow operators to fine-tune the granulation process according to the material being processed.

- **Automatic Feed Systems**: These systems ensure a consistent supply of raw materials, improving granulation efficiency.

- **Automation Features**: Advanced controls for monitoring and adjusting parameters can lead to better quality granules.

The right adjustments can significantly impact the uniformity and quality of the granules produced.

Maintenance and Durability

Regular maintenance is essential for the longevity of any machinery, and disc pan granulators are no exception. Consider the following for optimal durability:

- **Ease of Maintenance**: Look for features that allow for easy access to components for cleaning and repairs.

- **Durability Ratings**: Research the manufacturer’s claims and look for user reviews that speak to the granulator's durability under continuous use.

Investing in a granulator that is easy to maintain can save you time and money in the long run.

Energy Efficiency

In today's eco-conscious environment, **energy efficiency** is a significant factor when choosing agricultural equipment.

- **Energy Consumption**: Evaluate the energy consumption rates of different models. Advanced technologies may offer lower energy usage without sacrificing performance.

- **Sustainability**: Look for granulators that meet sustainability standards and contribute to reduced carbon footprints.

An energy-efficient granulator will not only lower your operational costs but also align your business with sustainable practices.

Cost Considerations

When investing in a disc pan granulator, it’s important to analyze the **cost considerations** to ensure a good return on investment (ROI):

- **Initial Cost vs. Long-Term Value**: While a cheaper model may seem appealing, consider the long-term operational costs, potential repairs, and efficiency of the machine.

- **Financing Options**: Investigate financing options if upfront costs are a concern. Many manufacturers offer leasing or financing plans that can make high-quality equipment more accessible.

Understanding the cost structure will help you make a financially sound decision.

Choosing the Right Manufacturer

Selecting a reputable manufacturer is crucial for ensuring quality and reliability. Consider the following factors:

- **Reputation**: Research manufacturers’ reputations through customer reviews and industry accolades.

- **Customer Support**: Evaluate their customer service and support options. A manufacturer with strong post-purchase support can be invaluable.

- **Warranty and Service Agreements**: Look for manufacturers that offer warranties and service agreements, providing peace of mind for your investment.

Making an informed choice when selecting a manufacturer can significantly influence the success of your granulation efforts.

Conclusion

In conclusion, selecting the right disc pan granulator requires careful consideration of various essential features. By understanding the design, size, material quality, power requirements, adjustability, maintenance needs, energy efficiency, cost implications, and manufacturer reputation, you can make a well-informed decision. Investing in a high-quality granulator that meets your specific needs will enhance your production efficiency and product quality, positioning your agricultural business for success.

By following the guidelines and considerations outlined in this article, you will be well-equipped to choose the best disc pan granulator for your operational requirements, ensuring a smooth and efficient granulation process for years to come.

Enhancing Crop Yield: The Critical Role of Rotary Drum Granulation in Compound Fertilizer Production