Understanding the Role of Disc Pan Granulators in Agricultural Machinery

Release time:

Sep 05,2025

--- Disc Pan Granulators are essential pieces of equipment within the agricultural machinery sector, particularly in the production of fertilizers and soil amendments. These devices play a crucial role in the granulation process, where raw materials such as urea, ammonium nitrate, and various organic substances are transformed into uniform granules. This process not only enhances the efficiency of

---

Disc Pan Granulators are essential pieces of equipment within the agricultural machinery sector, particularly in the production of fertilizers and soil amendments. These devices play a crucial role in the granulation process, where raw materials such as urea, ammonium nitrate, and various organic substances are transformed into uniform granules. This process not only enhances the efficiency of fertilizer application but also contributes to better crop yields and soil health.

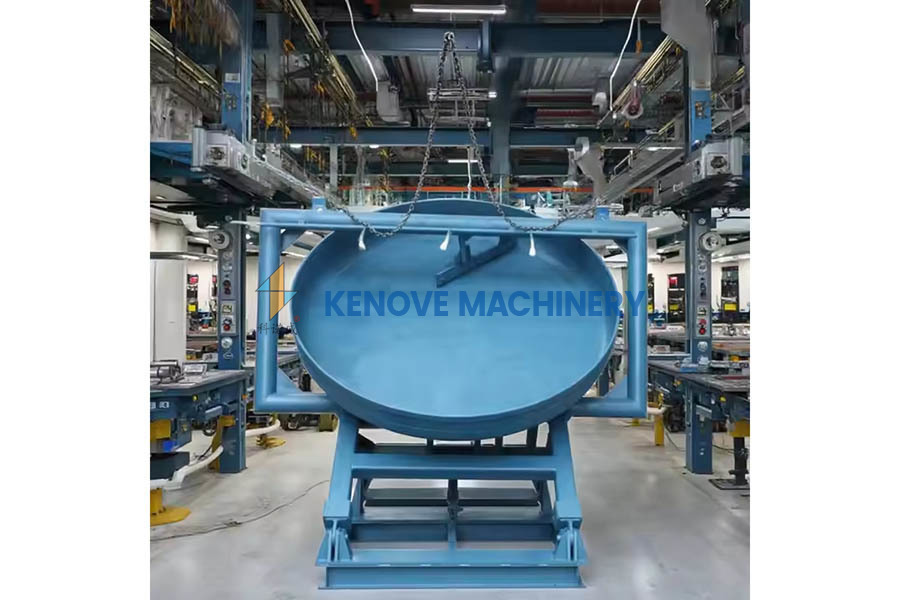

The operation of a Disc Pan Granulator revolves around its unique design, which typically features a circular pan that rotates at a specific angle. As the pan spins, the materials are fed into it, where they are subjected to centrifugal forces. These forces compel the materials to adhere to one another, forming granules of a desired size as they tumble in the pan. This method of granulation is highly efficient, allowing for rapid production of high-quality pellets that can be easily handled and applied in various agricultural settings.

One of the primary advantages of using Disc Pan Granulators is their ability to produce granules of uniform size and density. This uniformity is critical in ensuring that fertilizers distribute evenly across the soil, maximizing nutrient uptake by plants. Additionally, the granulation process helps reduce dust formation, improving the working environment for farmers and minimizing waste during application.

Furthermore, Disc Pan Granulators are highly versatile and can be adapted to handle a wide range of materials. This flexibility is particularly beneficial for producers looking to create customized fertilizers tailored to specific soil conditions or crop requirements. By adjusting parameters such as the feed rate, moisture content, and rotation speed, operators can fine-tune the granulation process to achieve the desired end product.

In addition to their operational efficiency, Disc Pan Granulators also contribute to sustainability in agriculture. By enabling the production of organic fertilizers and the recycling of agricultural by-products, these machines play a vital role in promoting eco-friendly farming practices. This not only helps in reducing reliance on chemical fertilizers but also enhances soil fertility and promotes a healthier ecosystem.

In conclusion, Disc Pan Granulators are a fundamental component of modern agricultural machinery, supporting the production of effective and efficient fertilizers. Their ability to create uniform granules, coupled with their adaptability and potential for sustainable practices, makes them an invaluable tool for farmers and agricultural producers alike. Understanding the role of these machines can help stakeholders make informed decisions regarding their use and investment in agricultural technologies.

Disc Pan Granulators are essential pieces of equipment within the agricultural machinery sector, particularly in the production of fertilizers and soil amendments. These devices play a crucial role in the granulation process, where raw materials such as urea, ammonium nitrate, and various organic substances are transformed into uniform granules. This process not only enhances the efficiency of fertilizer application but also contributes to better crop yields and soil health.

The operation of a Disc Pan Granulator revolves around its unique design, which typically features a circular pan that rotates at a specific angle. As the pan spins, the materials are fed into it, where they are subjected to centrifugal forces. These forces compel the materials to adhere to one another, forming granules of a desired size as they tumble in the pan. This method of granulation is highly efficient, allowing for rapid production of high-quality pellets that can be easily handled and applied in various agricultural settings.

One of the primary advantages of using Disc Pan Granulators is their ability to produce granules of uniform size and density. This uniformity is critical in ensuring that fertilizers distribute evenly across the soil, maximizing nutrient uptake by plants. Additionally, the granulation process helps reduce dust formation, improving the working environment for farmers and minimizing waste during application.

Furthermore, Disc Pan Granulators are highly versatile and can be adapted to handle a wide range of materials. This flexibility is particularly beneficial for producers looking to create customized fertilizers tailored to specific soil conditions or crop requirements. By adjusting parameters such as the feed rate, moisture content, and rotation speed, operators can fine-tune the granulation process to achieve the desired end product.

In addition to their operational efficiency, Disc Pan Granulators also contribute to sustainability in agriculture. By enabling the production of organic fertilizers and the recycling of agricultural by-products, these machines play a vital role in promoting eco-friendly farming practices. This not only helps in reducing reliance on chemical fertilizers but also enhances soil fertility and promotes a healthier ecosystem.

In conclusion, Disc Pan Granulators are a fundamental component of modern agricultural machinery, supporting the production of effective and efficient fertilizers. Their ability to create uniform granules, coupled with their adaptability and potential for sustainable practices, makes them an invaluable tool for farmers and agricultural producers alike. Understanding the role of these machines can help stakeholders make informed decisions regarding their use and investment in agricultural technologies.

Enhancing Crop Yield: The Critical Role of Rotary Drum Granulation in Compound Fertilizer Production