Enhancing Crop Yield: The Critical Role of Rotary Drum Granulation in Compound Fertilizer Production

Release time:

Sep 08,2025

Enhancing Crop Yield: The Critical Role of Rotary Drum Granulation in Compound Fertilizer Production Table of Contents 1. Introduction to Crop Yield Enhancement 2. The Importance of Fertilizers in Agriculture 3. Understanding Compound Fertilizers 4. The Granulation Process Explained 5. What is Rotary Drum Granulation? 6. Advantages of Rotary Drum Granulation 7. Impact of Rotary Drum

Enhancing Crop Yield: The Critical Role of Rotary Drum Granulation in Compound Fertilizer Production

Table of Contents

- 1. Introduction to Crop Yield Enhancement

- 2. The Importance of Fertilizers in Agriculture

- 3. Understanding Compound Fertilizers

- 4. The Granulation Process Explained

- 5. What is Rotary Drum Granulation?

- 6. Advantages of Rotary Drum Granulation

- 7. Impact of Rotary Drum Granulation on Crop Yield

- 8. Innovative Practices in Fertilizer Production

- 9. Conclusion

- 10. FAQs

1. Introduction to Crop Yield Enhancement

In today's competitive agricultural landscape, **enhancing crop yield** is paramount for ensuring food security and improving farmers' livelihoods. As global demand for food rises, innovative practices and technologies are crucial to increase productivity. One such technology is **rotary drum granulation**, an effective method employed in the production of compound fertilizers. This article delves into its significance and role in boosting crop yields.

2. The Importance of Fertilizers in Agriculture

Fertilizers are vital for modern agriculture, supplying essential nutrients that enhance plant growth and development. They replenish soil nutrients depleted by continuous cropping and improve soil structure. Without the use of fertilizers, many soils would be unable to support the nutritional needs of crops, leading to diminished yields.

2.1 Types of Fertilizers

Various fertilizers are used in agriculture, broadly categorized into:

- **Organic Fertilizers:** Derived from natural sources (e.g., manure, compost).

- **Inorganic Fertilizers:** Manufactured through chemical processes, often containing specific nutrient ratios.

Compound fertilizers, which combine multiple nutrients, have gained popularity due to their balanced nutrient profile.

3. Understanding Compound Fertilizers

Compound fertilizers are formulations that contain two or more essential nutrients, typically nitrogen (N), phosphorus (P), and potassium (K). These fertilizers are designed to provide a balanced supply of nutrients for crops, ensuring optimal growth.

3.1 Benefits of Compound Fertilizers

- **Nutrient Efficiency:** Delivering multiple nutrients in one application reduces the risk of nutrient deficiency.

- **Convenience:** Simplifies fertilizer application, saving time and labor for farmers.

- **Reduced Environmental Impact:** Optimized nutrient delivery minimizes runoff, protecting local ecosystems.

4. The Granulation Process Explained

Granulation is the process of forming granules from powdered materials. In fertilizer production, this process improves the physical and chemical properties of the fertilizers, leading to enhanced performance.

4.1 Stages of the Granulation Process

1. **Mixing:** Raw materials are combined to achieve the desired nutrient composition.

2. **Granulation:** The mixed materials are agglomerated into granules using moisture and agitation.

3. **Drying:** Granules are dried to remove excess moisture, ensuring stability and preventing clumping.

4. **Cooling:** The dried granules are cooled to room temperature, preparing them for packaging.

5. What is Rotary Drum Granulation?

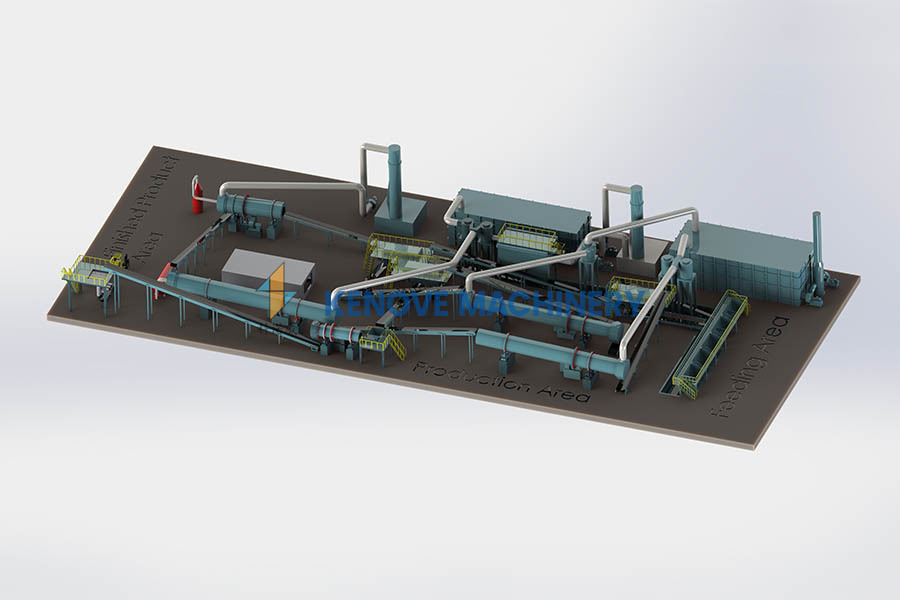

Rotary drum granulation is a specific technique within the granulation process. It involves the use of a rotating drum to create granules from a mixture of materials. The drum's rotation promotes the agglomeration of particles, leading to the formation of uniform, spherical granules.

5.1 Key Components of Rotary Drum Granulators

- **Drum:** The main body where granulation occurs.

- **Feeder:** Introduces raw materials into the drum.

- **Spray System:** Applies moisture or binders to facilitate granulation.

- **Discharge Mechanism:** Removes finished granules from the drum.

6. Advantages of Rotary Drum Granulation

Rotary drum granulation offers several benefits that contribute to its popularity in the fertilizer industry.

6.1 Enhanced Granule Quality

The rotary motion ensures even distribution of moisture and materials, resulting in uniform granule size and density. This consistency improves nutrient release rates and application efficiency.

6.2 Increased Production Capacity

Rotary drum granulators can handle large volumes of materials, allowing for high-throughput production. This scalability is ideal for meeting the growing demand for fertilizers.

6.3 Lower Operating Costs

The efficiency of rotary drum granulation translates to lower energy consumption and reduced labor costs. Additionally, the process generates less waste, further enhancing cost-effectiveness.

7. Impact of Rotary Drum Granulation on Crop Yield

The influence of rotary drum granulation on crop yield can be significant. By producing high-quality compound fertilizers, it enhances nutrient availability, promoting healthier plant growth.

7.1 Nutrient Release Profiles

The uniform granules created through rotary drum granulation exhibit controlled nutrient release profiles, ensuring that crops receive the necessary nutrients over time. This sustained availability maximizes nutrient uptake and minimizes losses.

7.2 Improved Soil Health

When applied correctly, compound fertilizers produced through rotary drum granulation contribute to improved soil structure and fertility. Healthy soils retain moisture better and support diverse microbial life, further enhancing crop yields.

8. Innovative Practices in Fertilizer Production

As the agricultural sector evolves, incorporating technology and best practices in fertilizer production has become essential.

8.1 Precision Agriculture

Utilizing data-driven approaches enables farmers to apply fertilizers more efficiently, tailoring applications to specific crop needs and soil conditions.

8.2 Sustainable Practices

Integrating organic matter and adopting sustainable practices in conjunction with rotary drum granulation can enhance fertilizer effectiveness while promoting environmental stewardship.

9. Conclusion

Rotary drum granulation plays a pivotal role in the production of compound fertilizers, significantly enhancing crop yields. By understanding the granulation process and its benefits, farmers and agribusinesses can leverage this technology to improve their agricultural practices. The continued adoption of innovative fertilizer production methods will be crucial in meeting the increasing food demands of the global population, ensuring a sustainable future for agriculture.

10. FAQs

What are the primary benefits of using rotary drum granulation in fertilizer production?

Rotary drum granulation improves granule quality, increases production capacity, and reduces operating costs, making it a preferred choice for fertilizer manufacturers.

How does rotary drum granulation enhance nutrient availability for crops?

The uniform granules produced ensure a controlled nutrient release profile, allowing crops to absorb nutrients efficiently over time.

What types of fertilizers can be produced using rotary drum granulation?

Rotary drum granulation can be used to produce various compound fertilizers, including NPK (nitrogen-phosphorus-potassium) formulations.

Is rotary drum granulation environmentally friendly?

Yes, the process generates less waste and promotes the efficient use of materials, contributing to more sustainable fertilizer production.

How can farmers optimize fertilizer application for better crop yields?

By utilizing precision agriculture techniques, farmers can tailor fertilizer applications to match specific crop needs and soil conditions, maximizing yield potential.

Enhancing Crop Yield: The Critical Role of Rotary Drum Granulation in Compound Fertilizer Production