Why Choose Rotary Drum Granulation for Efficient Compound Fertilizer Manufacturing?

Release time:

Sep 16,2025

Why Choose Rotary Drum Granulation for Efficient Compound Fertilizer Manufacturing? Compound fertilizers play a crucial role in modern agriculture, providing essential nutrients to crops and enhancing yield. Among the various manufacturing techniques available, **rotary drum granulation** stands out for its efficiency and effectiveness. In this article, we will delve into the numerous advantages o

Why Choose Rotary Drum Granulation for Efficient Compound Fertilizer Manufacturing?

Compound fertilizers play a crucial role in modern agriculture, providing essential nutrients to crops and enhancing yield. Among the various manufacturing techniques available, **rotary drum granulation** stands out for its efficiency and effectiveness. In this article, we will delve into the numerous advantages of rotary drum granulation, explore the process in detail, and answer common questions to help you understand why this method is ideal for compound fertilizer manufacturing.

Understanding Rotary Drum Granulation

Rotary drum granulation is a widely used technique in the production of **granulated fertilizers**. It combines solid raw materials with liquids to form uniform granules through a continuous process in a rotating drum. This method offers a range of benefits that contribute to its popularity in the agricultural industry.

The Granulation Process Explained

The granulation process typically involves several key stages:

1. **Material Preparation**: Raw materials, including nitrogen, phosphorus, and potassium sources, are carefully selected and prepared.

2. **Mixing**: The prepared materials are mixed with water or other binding agents to create a homogeneous mixture.

3. **Granulation**: The mixture is fed into a rotating drum, where it is agitated. The rotation causes the particles to collide, promoting granule formation.

4. **Drying and Cooling**: Granules are then dried and cooled to enhance stability and prevent degradation.

This continuous process not only maximizes efficiency but also produces high-quality granules that are essential for effective nutrient delivery to plants.

Key Benefits of Rotary Drum Granulation

The rotary drum granulation technique offers several key advantages:

- **High Production Capacity**: The continuous nature of the process allows for large-scale production, meeting the increasing demand for fertilizers.

- **Uniform Granule Size**: Rotary drum granulation produces granules of consistent size and shape, leading to improved application rates and nutrient release.

- **Cost-Effectiveness**: With lower operational costs compared to batch processing methods, rotary drum granulation is a more economical choice for manufacturers.

- **Versatility**: This method can accommodate a variety of raw materials, making it suitable for producing different types of fertilizers.

Efficiency in Compound Fertilizer Manufacturing

Efficiency is a critical factor in fertilizer manufacturing, and rotary drum granulation excels in this area.

Optimizing Resource Use

The rotary drum granulation process is designed to minimize waste and maximize resource utilization. By using a continuous flow of materials and energy, manufacturers can reduce costs associated with energy consumption and raw material waste. **Efficient energy use** is crucial in lowering overall production costs, allowing manufacturers to provide competitive pricing in the market.

Streamlined Operations

The rotary drum granulation method integrates various manufacturing stages into a single system. This streamlining allows for faster production times and reduced labor costs, improving overall operational efficiency.

Environmental Considerations

With an increasing focus on sustainability in agriculture, the environmental impact of fertilizer manufacturing processes cannot be overlooked.

Reduced Emissions

One of the significant advantages of rotary drum granulation is its potential to reduce harmful emissions. By optimizing the granulation process and utilizing modern equipment, manufacturers can limit greenhouse gas emissions and other pollutants, contributing to a cleaner environment.

Eco-Friendly Raw Materials

Rotary drum granulation can also accommodate organic and eco-friendly raw materials, enabling manufacturers to produce fertilizers that align with sustainable agricultural practices. This flexibility supports a growing market for environmentally friendly products.

Cost-Effectiveness of Rotary Drum Granulation

In today's competitive fertilizer market, cost-effectiveness is essential for manufacturers looking to thrive.

Lower Production Costs

The continuous nature of rotary drum granulation minimizes downtime, allowing for higher output and reduced production costs. Additionally, the efficient use of resources leads to lower raw material expenses, making this method an attractive option for manufacturers seeking to bolster their bottom line.

Long-Term Financial Benefits

Investing in rotary drum granulation technology can yield substantial long-term financial benefits. The initial capital expenditure is often offset by reduced operational costs and increased production efficiency, resulting in a favorable return on investment.

Implementing Rotary Drum Granulation in Your Manufacturing Process

For manufacturers considering the transition to rotary drum granulation, several steps should be taken to ensure a smooth implementation.

Assessing Your Current Processes

Begin by evaluating your existing manufacturing processes. Identify areas for improvement, such as production efficiency, cost reduction, and environmental impact. This assessment will help you determine how rotary drum granulation can fit into your operations.

Investing in Technology

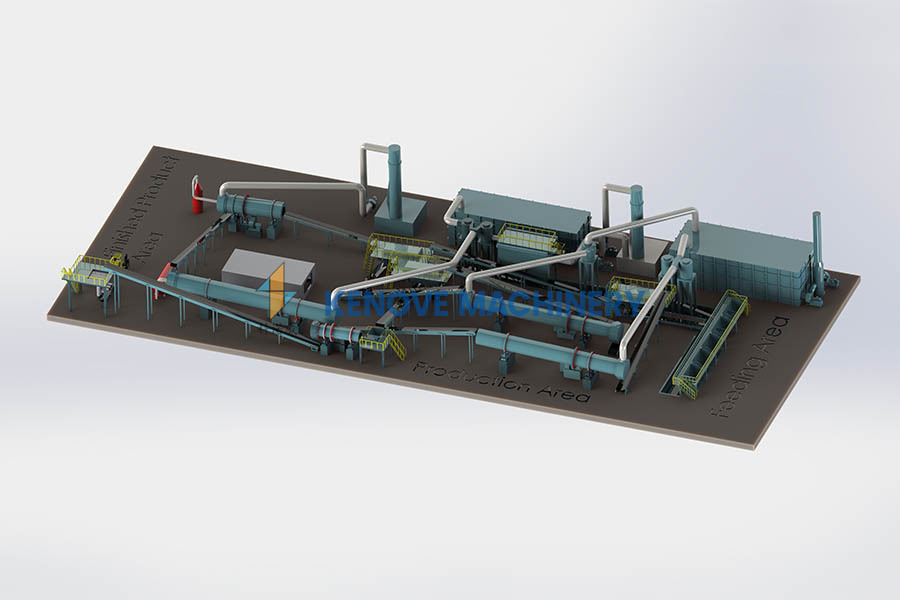

Selecting the right equipment is critical for successful implementation. Invest in high-quality rotary drum granulators designed for your specific production needs. Collaborating with experienced suppliers can ensure you choose the right technology for optimal performance.

FAQs About Rotary Drum Granulation

1. What materials can be used in rotary drum granulation?

Rotary drum granulation can accommodate a variety of raw materials, including nitrogen, phosphorus, and potassium sources, as well as organic materials.

2. How does rotary drum granulation improve fertilizer quality?

The process creates uniform granules of consistent size, leading to better nutrient delivery and improved crop yields.

3. Is rotary drum granulation environmentally friendly?

Yes, by reducing emissions and allowing for the use of eco-friendly raw materials, rotary drum granulation supports sustainable agricultural practices.

4. What are the initial costs associated with rotary drum granulation?

While the initial investment in equipment may be significant, the long-term cost savings from increased efficiency and lower operational costs often justify the expenditure.

5. Can rotary drum granulation be integrated into existing manufacturing processes?

Yes, rotary drum granulation can be seamlessly integrated into current production lines with proper assessment and investment in suitable technology.

Conclusion

In conclusion, **rotary drum granulation** presents a highly efficient and cost-effective method for manufacturing compound fertilizers. With its ability to produce uniform granules, optimize resource use, and reduce environmental impact, this technique is well-suited to meet the demands of modern agriculture. By considering the numerous benefits and implementing the necessary technology, manufacturers can enhance their production capabilities and contribute to sustainable farming practices. Adopting rotary drum granulation not only positions manufacturers for success but also helps deliver high-quality fertilizers that support global food security.