The Advantages of Extrusion Granulation in Compound Fertilizer Production

Release time:

Sep 16,2025

Extrusion granulation is a revolutionary technique in compound fertilizer production that has gained traction in recent years due to its numerous benefits. This method involves the continuous mixing of raw materials, followed by the application of heat and pressure to form granules. The process not only enhances the nutrient content but also improves the physical properties of fertilizers, making

Extrusion granulation is a revolutionary technique in compound fertilizer production that has gained traction in recent years due to its numerous benefits. This method involves the continuous mixing of raw materials, followed by the application of heat and pressure to form granules. The process not only enhances the nutrient content but also improves the physical properties of fertilizers, making them more effective for agricultural applications.

One of the primary advantages of extrusion granulation is the uniformity of the fertilizer produced. The controlled conditions during the extrusion process allow for an even distribution of nutrients, ensuring that plants receive a balanced supply of essential elements. This uniformity is crucial for crop health and yield, as it helps prevent nutrient deficiencies or excesses that can hinder plant growth.

Moreover, extrusion granulation enhances the solubility of fertilizers. The heat generated during the extrusion process helps to create a more reactive material, allowing for quicker absorption by plants. This increased solubility means that farmers can expect faster results from their fertilizer applications, leading to improved crop performance and productivity.

Another significant benefit of this method is the reduction in dust formation and the improved handling characteristics of the final product. Traditional methods of fertilizer production often lead to dust and fines that can cause environmental issues and reduce the efficiency of application. In contrast, the granules produced through extrusion granulation are denser and less prone to dust formation, making them easier to transport and apply.

Additionally, extrusion granulation allows for the incorporation of various additives and micronutrients into the fertilizer matrix. This flexibility enables producers to tailor fertilizers to meet specific crop needs, enhancing overall agricultural efficiency. The ability to customize products based on soil health and crop requirements can lead to better resource management and sustainability in farming practices.

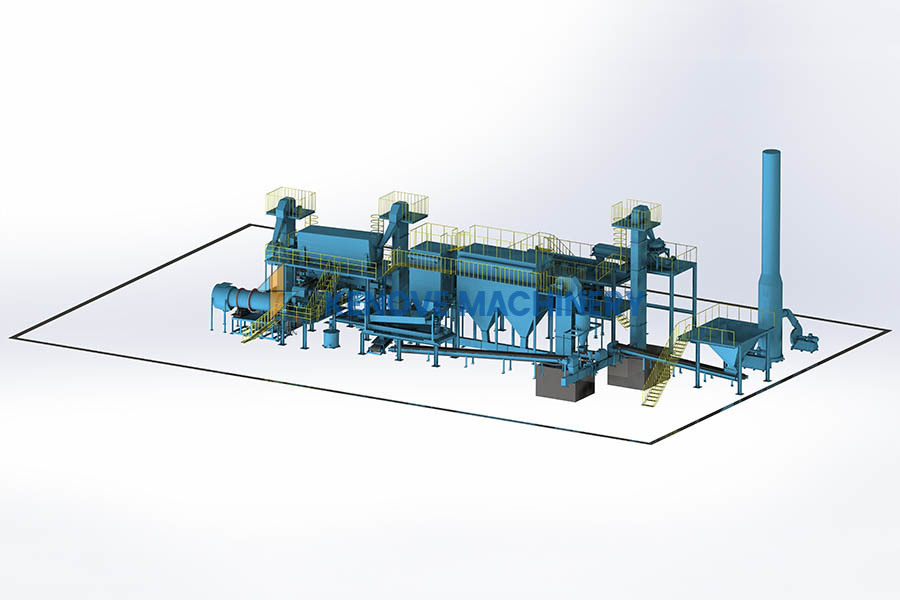

The technology behind extrusion granulation is continually evolving, with advancements in machinery and processing techniques. Modern equipment is designed to optimize energy use and minimize waste, making the production process more environmentally friendly. As the agricultural sector strives for sustainability, extrusion granulation stands out as a viable option that aligns with these goals.

In conclusion, extrusion granulation in compound fertilizer production offers several advantages, including uniform nutrient distribution, enhanced solubility, reduced dust formation, and the ability to customize formulations. As the demand for effective and sustainable agricultural practices grows, understanding the benefits of this innovative process can help farmers and producers make informed decisions for their operations. By adopting modern techniques like extrusion granulation, the agricultural industry can continue to improve productivity while minimizing environmental impact.

One of the primary advantages of extrusion granulation is the uniformity of the fertilizer produced. The controlled conditions during the extrusion process allow for an even distribution of nutrients, ensuring that plants receive a balanced supply of essential elements. This uniformity is crucial for crop health and yield, as it helps prevent nutrient deficiencies or excesses that can hinder plant growth.

Moreover, extrusion granulation enhances the solubility of fertilizers. The heat generated during the extrusion process helps to create a more reactive material, allowing for quicker absorption by plants. This increased solubility means that farmers can expect faster results from their fertilizer applications, leading to improved crop performance and productivity.

Another significant benefit of this method is the reduction in dust formation and the improved handling characteristics of the final product. Traditional methods of fertilizer production often lead to dust and fines that can cause environmental issues and reduce the efficiency of application. In contrast, the granules produced through extrusion granulation are denser and less prone to dust formation, making them easier to transport and apply.

Additionally, extrusion granulation allows for the incorporation of various additives and micronutrients into the fertilizer matrix. This flexibility enables producers to tailor fertilizers to meet specific crop needs, enhancing overall agricultural efficiency. The ability to customize products based on soil health and crop requirements can lead to better resource management and sustainability in farming practices.

The technology behind extrusion granulation is continually evolving, with advancements in machinery and processing techniques. Modern equipment is designed to optimize energy use and minimize waste, making the production process more environmentally friendly. As the agricultural sector strives for sustainability, extrusion granulation stands out as a viable option that aligns with these goals.

In conclusion, extrusion granulation in compound fertilizer production offers several advantages, including uniform nutrient distribution, enhanced solubility, reduced dust formation, and the ability to customize formulations. As the demand for effective and sustainable agricultural practices grows, understanding the benefits of this innovative process can help farmers and producers make informed decisions for their operations. By adopting modern techniques like extrusion granulation, the agricultural industry can continue to improve productivity while minimizing environmental impact.