Fertilizer Production Line

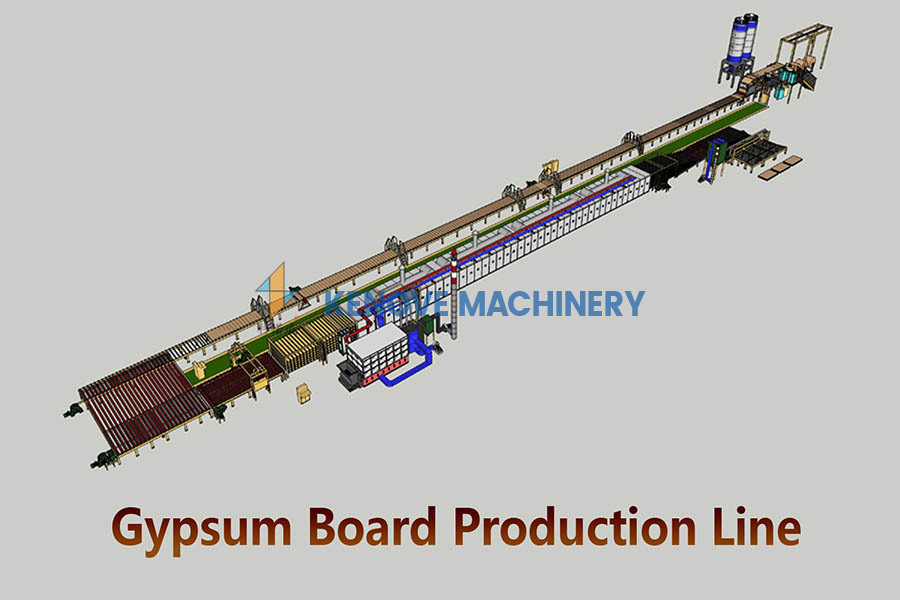

Gypsum Board Production Line Equipment

Category:

E-mail:

Gypsum board production line 30000-300000Tons/Year

The equipment of the gypsum board production line mainly includes raw material supply, board manufacturing, conveying, drying and edge cutting systems. The following is an introduction to the main equipment of each system:

Raw material supply system

- Crusher: Common types include the DSJ series drying hammer crusher, which can break large-sized gypsum ores or desulfurized gypsum sludge cakes with a moisture content of ≤ 12% into small particles smaller than 30mm.

- Mill: Usually used in conjunction with a crusher, such as a ball mill, to grind the small pieces of gypsum that have been crushed into finer powder, so that it reaches the required fineness for production.

- Mixing equipment: It includes metering pumps, fully automatic metering belt scales, etc., which can achieve precise measurement and transportation of main and auxiliary materials such as modified starch, retardant, pulp, water reducer, water, foaming agent, accelerator and gypsum powder.

Board manufacturing system

- Mixer: Mix all the measured main and auxiliary materials in the mixer to form a uniform gypsum slurry.

- Forming machine: For example, the LB-4 type hydraulic automatic walking gypsum wall panel forming machine can combine gypsum slurry with the upper and lower paper sheets, extrude gypsum panels of the required specifications, and also enable the formation of two gypsum wall panels at one time.

- Vibrating platform: Located below the forming machine, it vibrates to evenly distribute the gypsum slurry on the paper sheets, improving the density and uniformity of the gypsum panels.

Transportation system

- Conveying roller track: It is used to transport gypsum board materials, enabling them to move smoothly between various processes on the production line. During the conveying process, the gypsum board completes its final setting.

- Lateral machine: It consists of 1# lateral machine and 2# lateral machine. The 1# lateral machine is used to turn the gypsum board, while the 2# lateral machine is used to perform operations such as cutting the gypsum board to a fixed length.

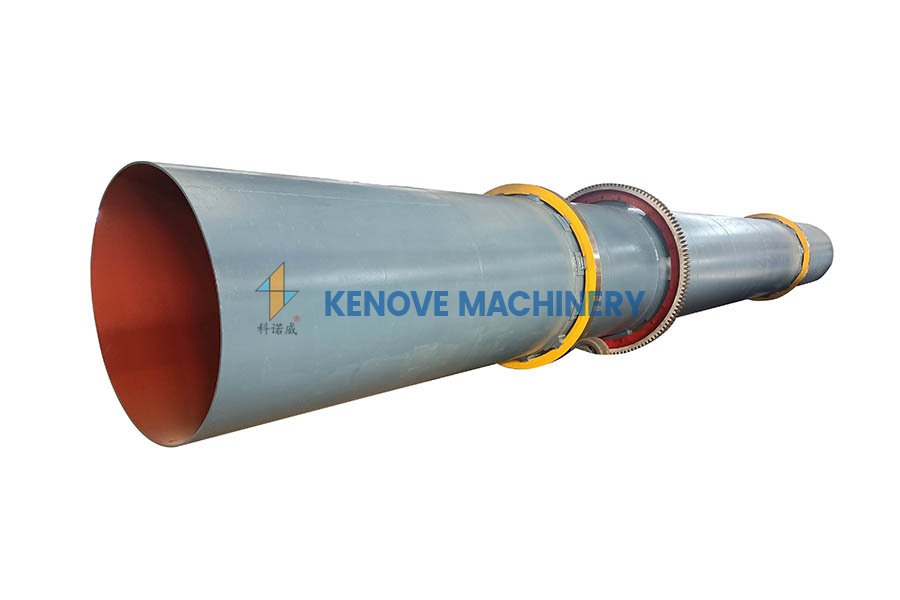

Drying system

- Drying machine: Usually, a fuel-type heat transfer oil furnace is used as the heat source. The hot oil passes through the finned heat exchanger to exchange heat with the air, and then is sent into the drying machine by the fan to dry the gypsum board, removing moisture and making the gypsum board reach the specified moisture content.

- Heat recovery system: Some advanced production lines are equipped with heat recovery systems, which can recover the residual heat generated during the drying process and use it to preheat raw materials or other sections that require thermal energy, thereby reducing energy consumption.

Edge trimming system

- Fixed-length cutting machine: Based on the preset length, it cuts the incoming gypsum boards into the required lengths, such as 2400mm, 3000mm, etc.

- Edge trimming machine: It trims the edges of the dried gypsum boards to remove the excess parts at the edges, making the dimensions of the gypsum boards more precise and the edges more straight.

key word:

SHIPPMENT DISPLAY

Application Case

WHY CHOOSE US

Less manufacturing experience, less than 10 years

Not a high-tech enterprise, outdated technology.

The market share of fertilizer equipment in China less than 1%.

No R&D team

No Investment

No Patents and property rights

The quality of the raw materials is not good.

The material thickness is very thin.

The lifespan is shorter.

Annual production of over 11000+

Equipment production bases

Professional technical R&D team

Over 300 types of products

FAQ